I have now been diagnosed as having a "Frozen Shoulder". There is no treatment for this, well not anything that is guaranteed to work. Doctors don't know much about it except that it usually cures itself in 18 months to 2 years. Resting it doesn't help so it is back to work on the car.

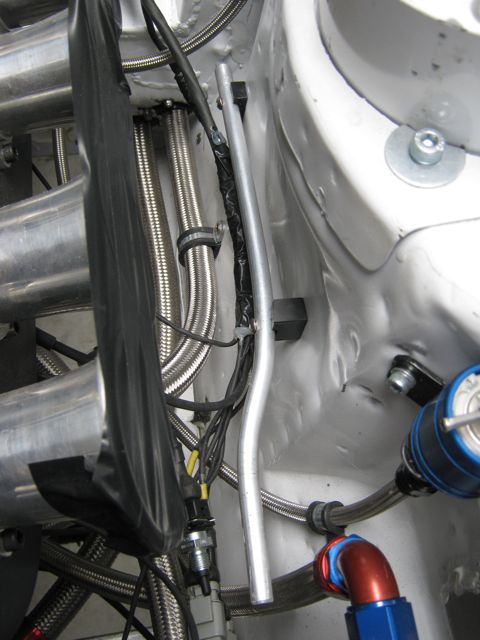

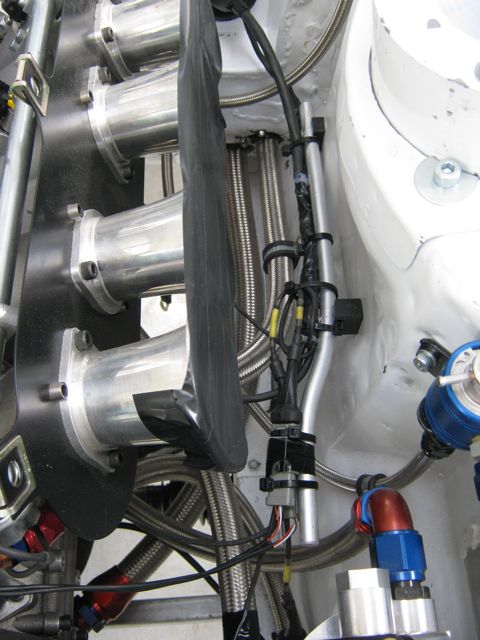

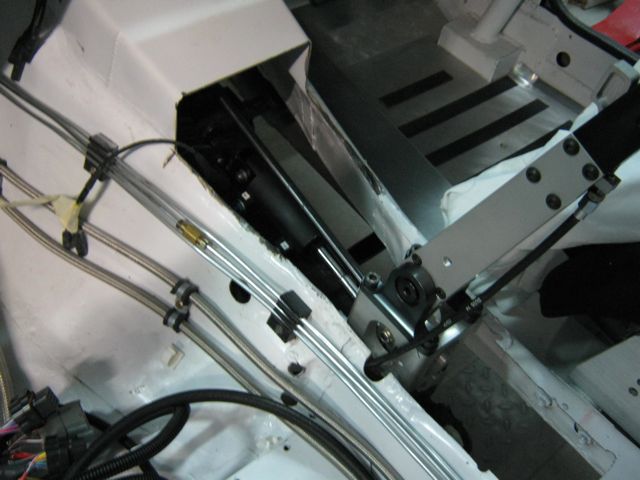

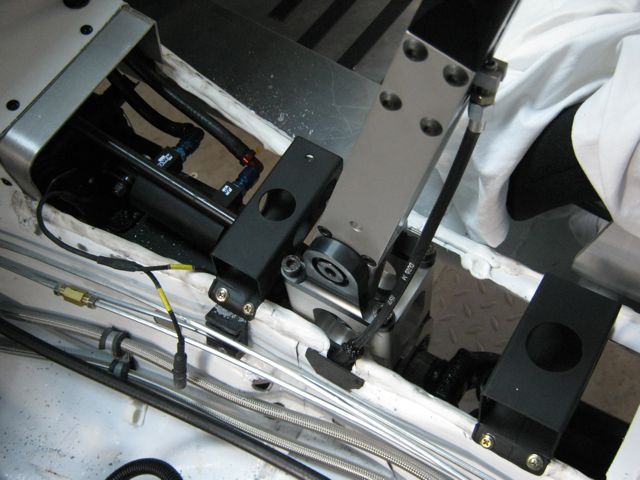

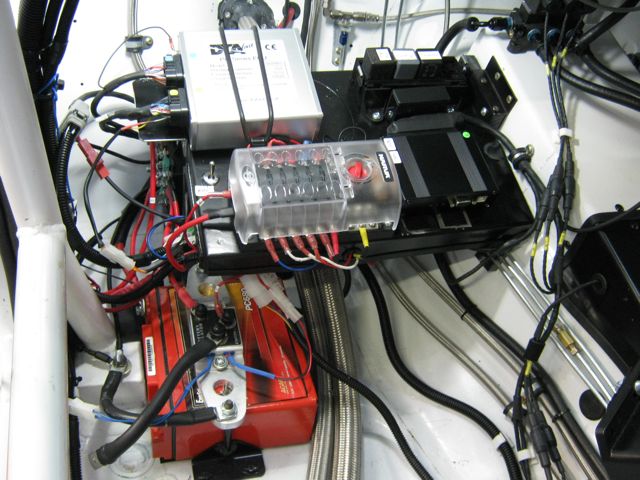

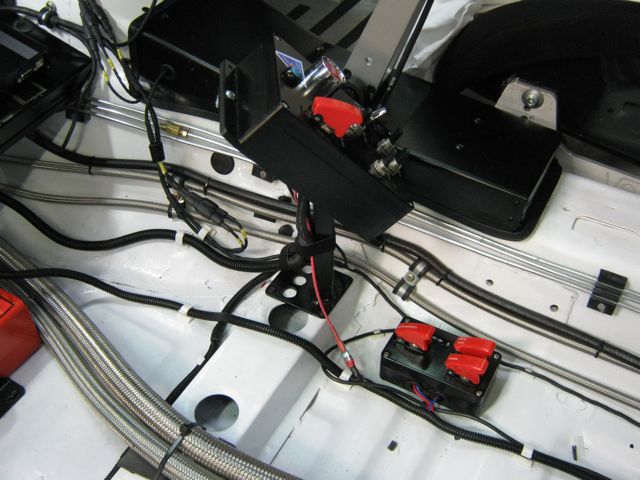

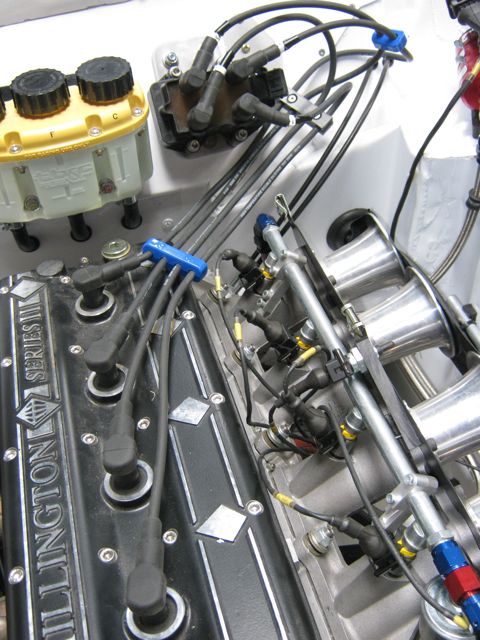

My mate John suggested I needed a support for the engine loom so I have made this

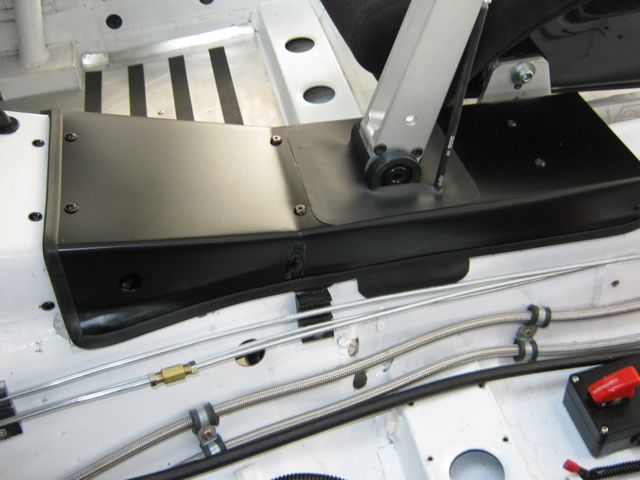

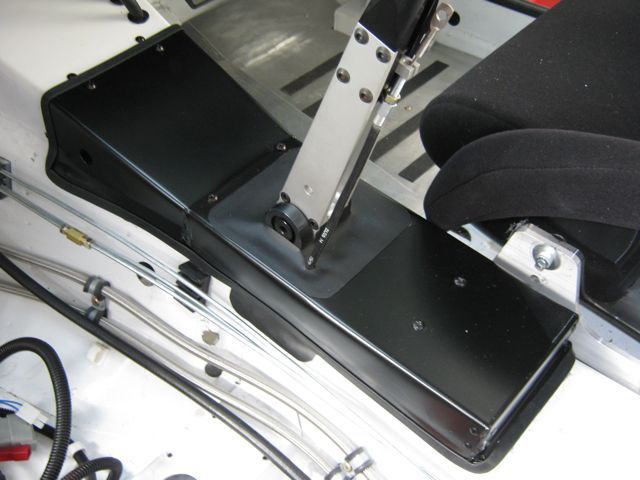

which has tidied it up nicely

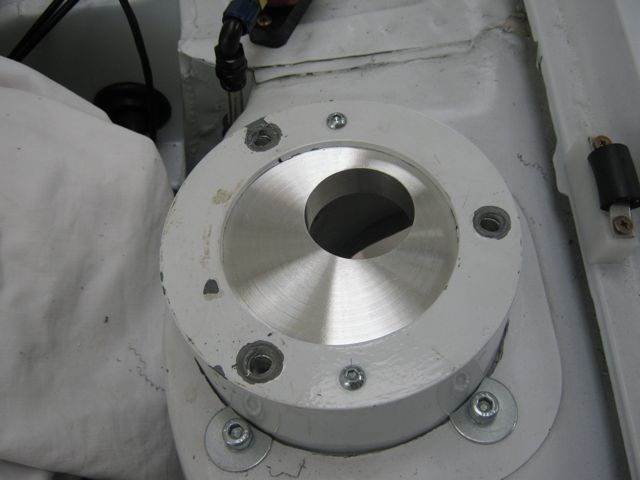

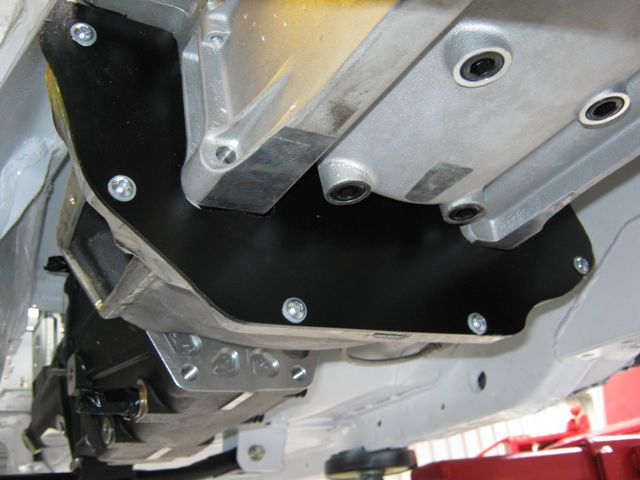

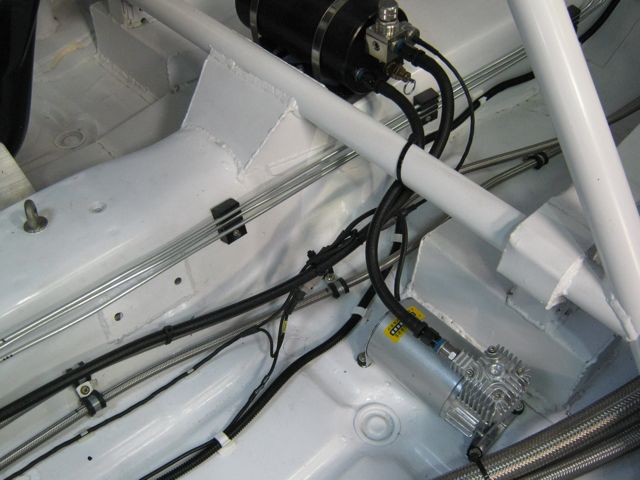

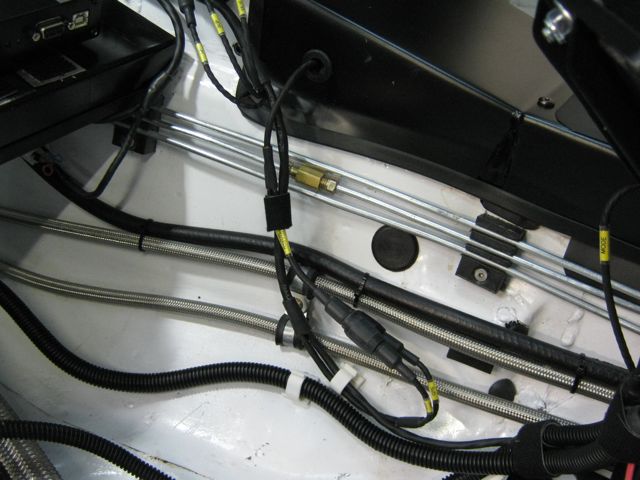

When I raised the front strut towers I didn't know the exact height I would need and they are a bit high to get the correct angle for the TCA at ride height so I have had some spacers made to lower the strut 20mm.

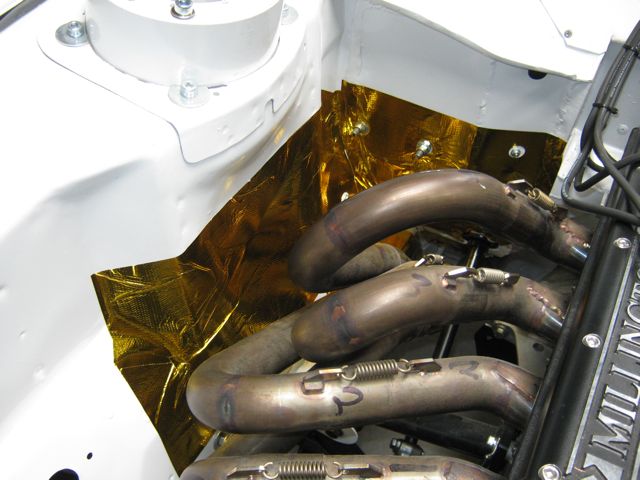

The extensions are looking a bit grotty so I need to paint them again.

Reply With Quote

Reply With Quote

gave me the answer.

gave me the answer.

?

?

Bookmarks