Hi. I am building a 1700 xflow after my other engine went bang. Now Iím no professional but I like to think I have the basics covered. I am going to post pictures here of the process and welcome your opinions on where I could be doing something differently.

I appreciate this wonít be as exciting as a cosworth but for me it will be!

Some of below is coming off the old engine but I have spent £1000 on new parts

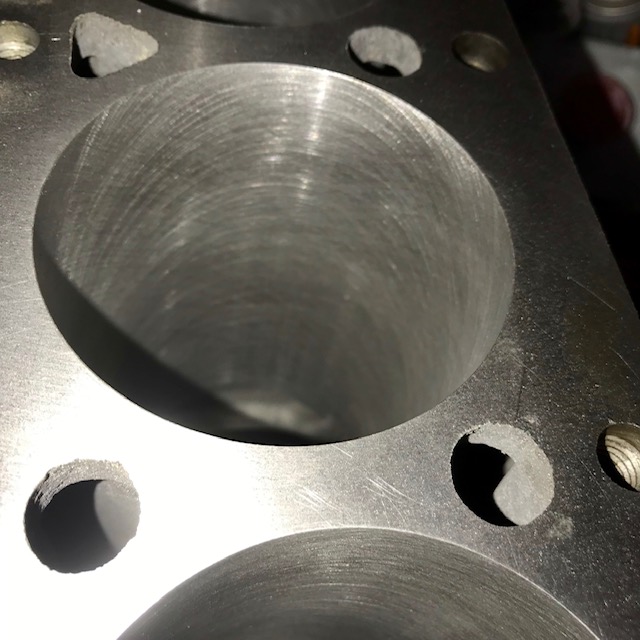

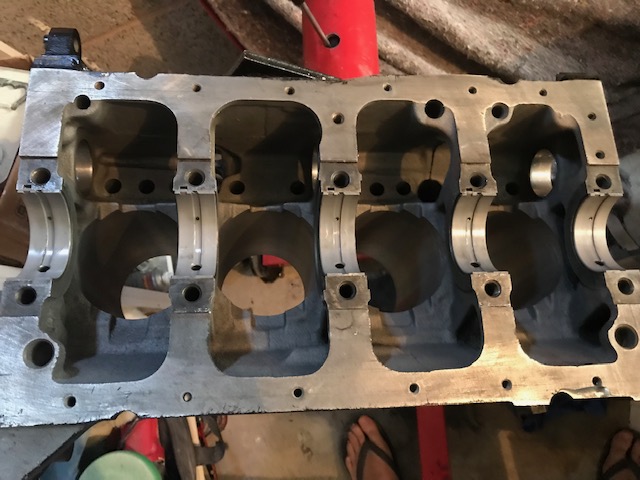

711m block acid cleaned and re bored

+110 pistons with deeper valve pockets

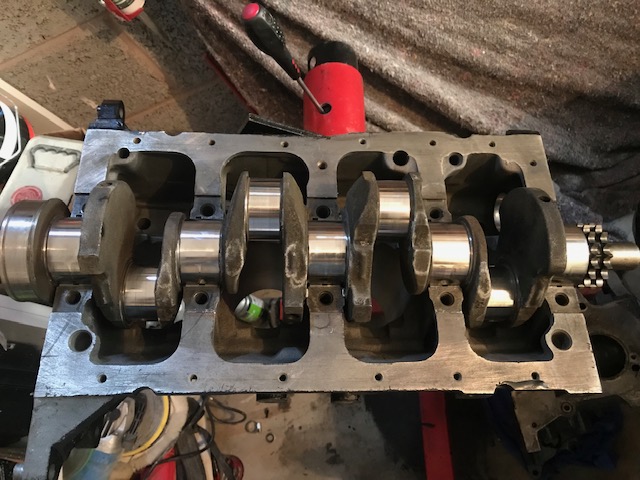

crank polished

244 cam

standard 1600 conrods

big valve head

duplex chain

steel rocker gear

high capacity oil pump

twin 40s

accuspark coil and dizzy

couple of questions to start with.

I am using Lucas engine assembly line. Any good?

Thrust bearings the correct way around?

i have lubed the back of main bearings. Is that good practice?

Do use assembly lube on main cap bolt threads?

Reply With Quote

Reply With Quote

Bookmarks