During the early part of lockdown i was browsing ebay looking for flowbenches/flowbench spares, when i spotted an ebay add for a superflow engine dyno, complete with a sound proof cell, with a starting price of £13,500.

my first thought, wow thats cheap! id seen others for sale but they were more like £30,000 just for the dyno.

second thought was who the hell is going to by that with the country under lockdown?

thirdly i didnt have that sort of money, potentially i could of borrowed it, but having just lost 90% of our custom and furloughed almost all my staff i didnt dare spend £13, let alone 1000 times that.

so the add expired and i did nothing, well almost, as i know people with dynos, and as someone interested in engine development it has to be the ultimate tool for me to own, my mind was racing.... i was watching loads of videos around dyno testing engines, yes i know rolling roads are good, but a dyno is better for development plus my landlords have stated specifically that i cannot have one on noise grounds.

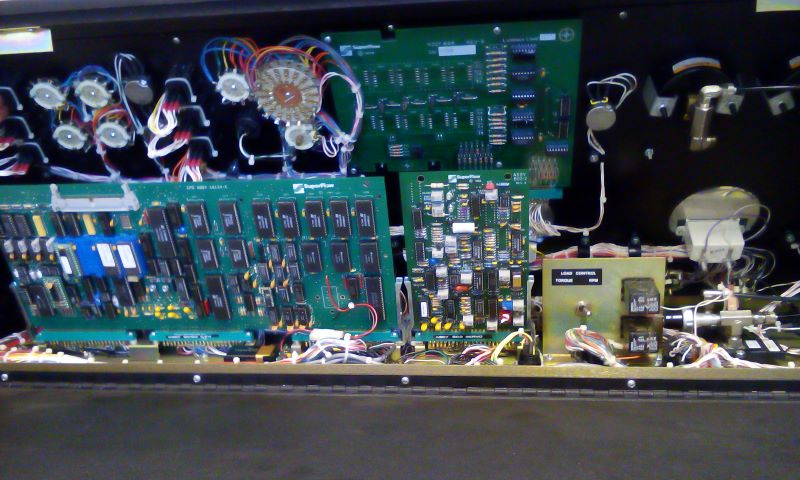

Superflow who are basically the only suppliers of engines dynos for the performance car engine market practically dont exist outside of the USA, but eventually i came across a uk supplier, came down to earth with a bump through when they told me a new 902 is £60,000 plus shipping, taxes and VAT, and thats just a basic dyno package itself.

a few more weeks went by and the Dyno re appeared on ebay, work was still rubbish, but i had stopped worrying we would go bankrupt literally anyday and i figured it was worth a bit of a lowball punt on the dyno, if we got in to real trouble financially i would sell a couple of my cars to recover the cost

so i stuck in a bid and went to look at it. i got it cheaper than the asking price, but flip side of that was i had to dismantle it all and transport it the 130miles back home myself. My Mate and MOT tester gave me a hand, to break it down in pieces, and transport it back, it took 4 days, we filled his citroen relay van twice, my sprinter 4 times and my car trailer twice

Reply With Quote

Reply With Quote

.jpg)

202mph standing mile

202mph standing mile

Does that mean you've got 2 of everything now then?

Does that mean you've got 2 of everything now then?

Bookmarks