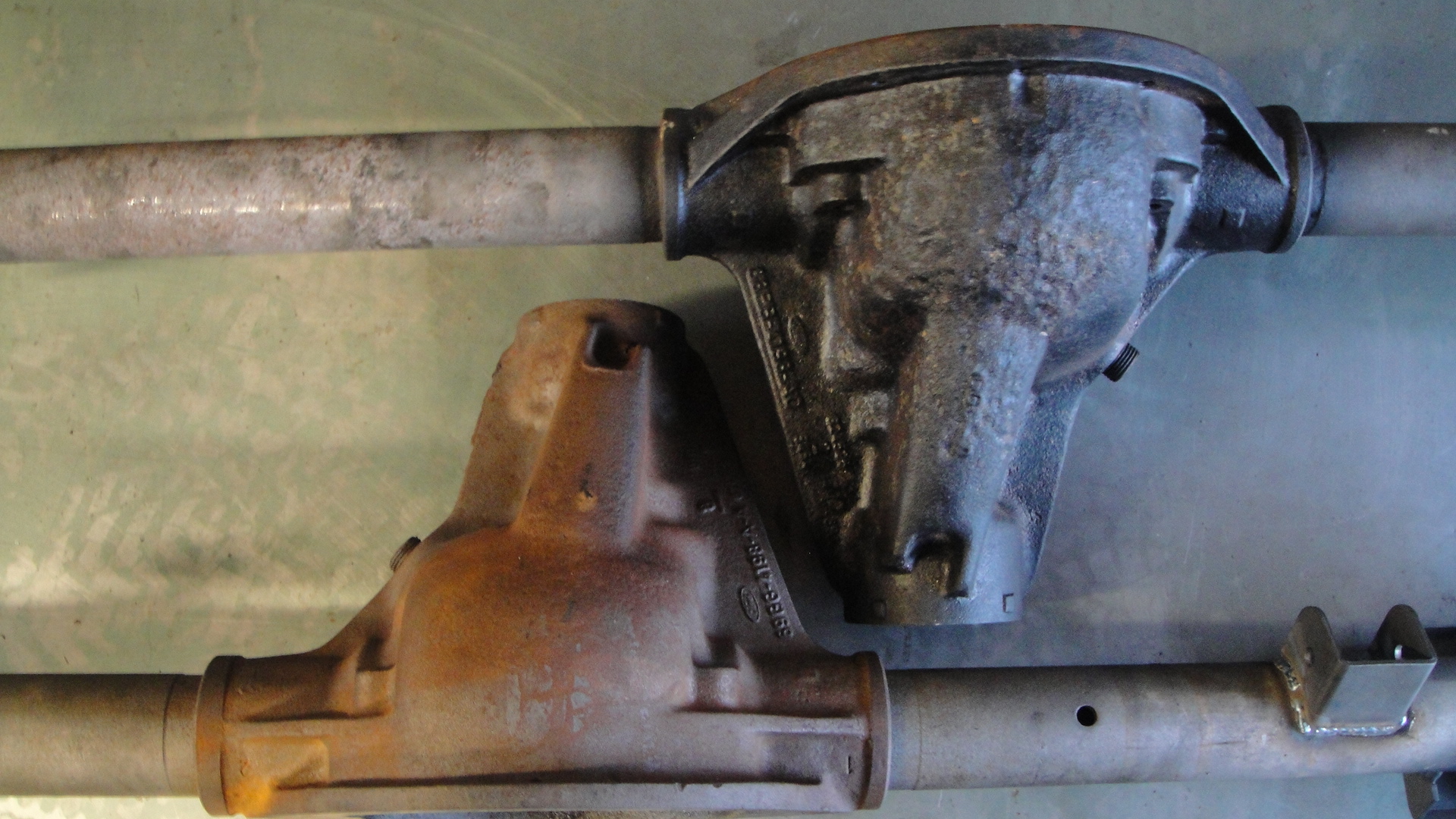

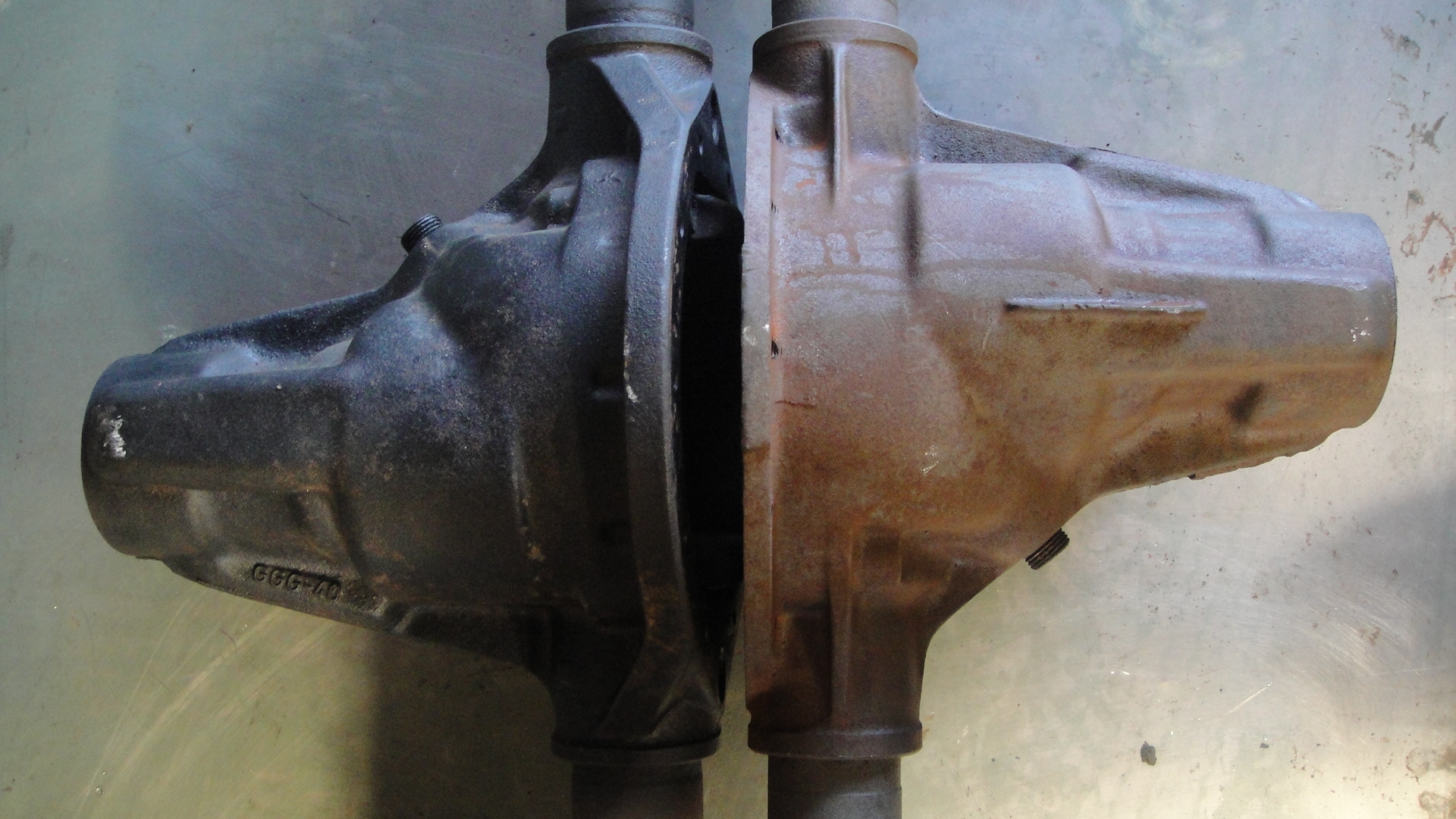

Basically i have bought a cheap atlas axle and i would like to shorten it and the shafts. I have read loads about people shortening thier own casings by tremoving the plug weld and lightly heating the pigs head to remove the tube. Then using a lathe to remove the right amount of material from the tube and then pressing the shortened one back in. The only problem is all of them don't tell you where the plug weld is. I am wondering if the weld is the big flat indent in the back of the pigs head on each side of the diff. If that is one is there any others? Also does anyone know of an engineering company who will respline the old shafts and 'case harden' them again. Thanks, for looking, John

Reply With Quote

Reply With Quote

When I grow up I will have a MK1 Escort

When I grow up I will have a MK1 Escort

%20(100x75).jpg)

I must be all growed up now then and paying for it!

I must be all growed up now then and paying for it!

)

)

Bookmarks