Evening all.

I am definately building this into a sprinter now and will be racing i the up to 1400cc modified production class, probably up at harewood and 2 sisters as they are closest. It's a long term project currently due to kids and getting wed next year, but i'm getting there bit by bit.

It's been a daily driver for a couple of years and neglected for a year or so so has deteriorated somewhat from when I first got it, so the first job is welding. Unfortunately I have to pay somebody else to do this, extra costs to the project but it will be done properly, the guys tasked to do it are very good, i'm hoping it will be out for welding around May time.

initially it will be road legal, but with the bare minimum to make it road legal. As it stands I have nowhere for a trailer so having it road legal means I can get it to the tracks and also have fun when i'm not racing. This is the first evolution of the car so further evolutions will probably mean pure race car for weight saving purposes and of course a daft cam.

this is the car in its prime.

and as it stands, in a damp, unpowered garage (but it's free )

)

The engine will be a 1300 ish kent crossflow to keep in class. As it stands the rules state the head is open, so i'm going pre crossflow. I'm doing this for a few reasons, one of them is not ultimate power. i'm going down this route because a crossflow head sucks warm, dead air from the bulkhead when using a standard twin carb manifold. the pre xflow obviously puts the inlets on the front of the head so gets lots of fresh, cold air for the engine. i have a good head with big valves and some nice porting work, just need to work on a compression ratio as the combustion chambers are too big.

To complete the conversion to this head I have some 1100 rods, longer than 1300 rods, and some flat top pistons which will need to be machined to deck height, possibly even the combustion chamber shape machined on to take help with compression.

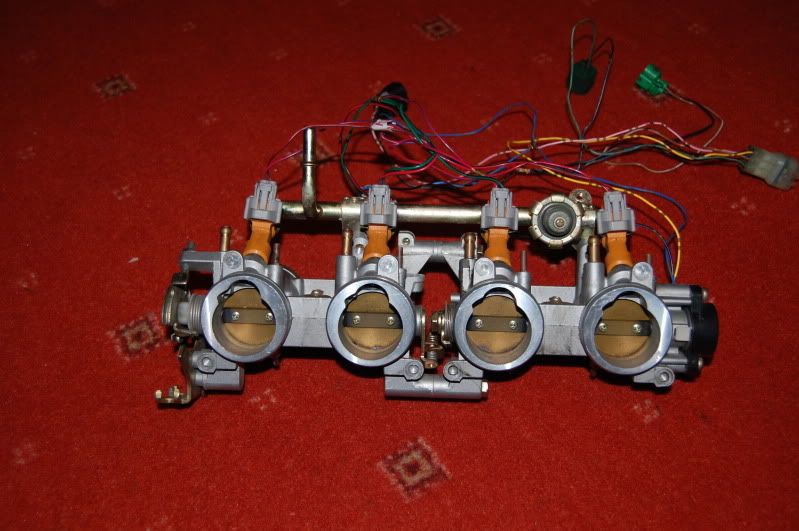

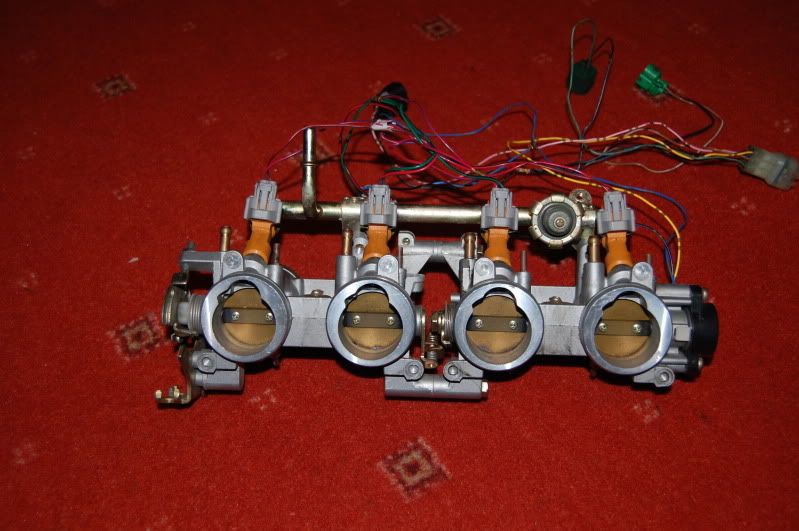

Plans are for a kent 244 or similar cam and it will be on throttle bodies and full engine management. I have some 36mm bodies to use which will be separated and I may use my twin carb inlet as this has been port matched to my head.

I've also got some fancy Leda front struts with remote oil resevoirs, from a mk2 racer.

So lots and lots to do but can't wait to get out in it once more, this is my first car and has been evolving since I got it, now i've finished uni and have a decent job, and of course somewhere to store the bugger, I can crack on with getting stuff done. Time allowing of course, 2 kids hampers progress quite often although the mrs. is very understanding fortunately

I am definately building this into a sprinter now and will be racing i the up to 1400cc modified production class, probably up at harewood and 2 sisters as they are closest. It's a long term project currently due to kids and getting wed next year, but i'm getting there bit by bit.

It's been a daily driver for a couple of years and neglected for a year or so so has deteriorated somewhat from when I first got it, so the first job is welding. Unfortunately I have to pay somebody else to do this, extra costs to the project but it will be done properly, the guys tasked to do it are very good, i'm hoping it will be out for welding around May time.

initially it will be road legal, but with the bare minimum to make it road legal. As it stands I have nowhere for a trailer so having it road legal means I can get it to the tracks and also have fun when i'm not racing. This is the first evolution of the car so further evolutions will probably mean pure race car for weight saving purposes and of course a daft cam.

this is the car in its prime.

and as it stands, in a damp, unpowered garage (but it's free

)

)

The engine will be a 1300 ish kent crossflow to keep in class. As it stands the rules state the head is open, so i'm going pre crossflow. I'm doing this for a few reasons, one of them is not ultimate power. i'm going down this route because a crossflow head sucks warm, dead air from the bulkhead when using a standard twin carb manifold. the pre xflow obviously puts the inlets on the front of the head so gets lots of fresh, cold air for the engine. i have a good head with big valves and some nice porting work, just need to work on a compression ratio as the combustion chambers are too big.

To complete the conversion to this head I have some 1100 rods, longer than 1300 rods, and some flat top pistons which will need to be machined to deck height, possibly even the combustion chamber shape machined on to take help with compression.

Plans are for a kent 244 or similar cam and it will be on throttle bodies and full engine management. I have some 36mm bodies to use which will be separated and I may use my twin carb inlet as this has been port matched to my head.

I've also got some fancy Leda front struts with remote oil resevoirs, from a mk2 racer.

So lots and lots to do but can't wait to get out in it once more, this is my first car and has been evolving since I got it, now i've finished uni and have a decent job, and of course somewhere to store the bugger, I can crack on with getting stuff done. Time allowing of course, 2 kids hampers progress quite often although the mrs. is very understanding fortunately