Re: Graham's bmw 2002 race car.

when you back out ?

when you back out ?

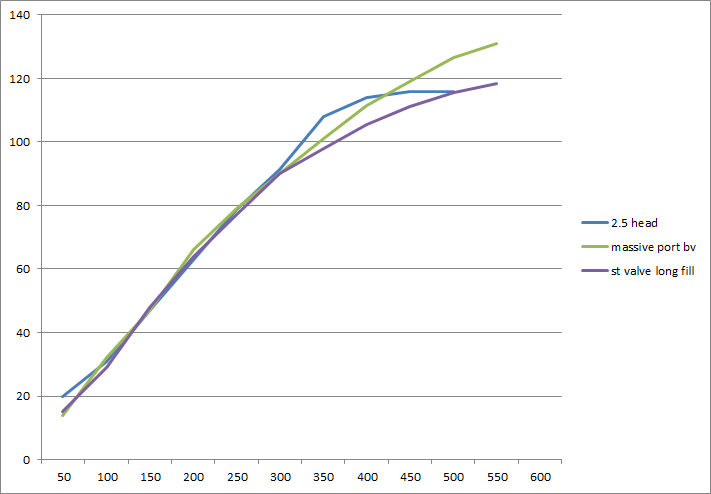

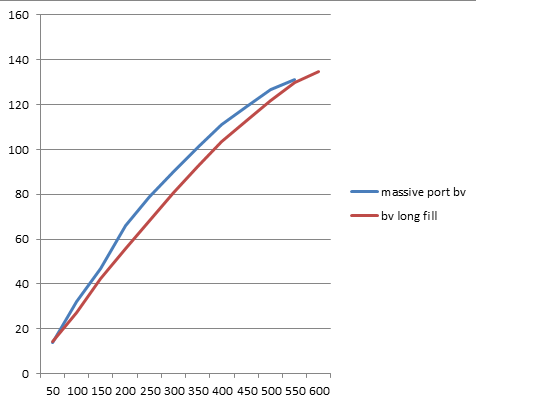

the big valve previously lost out massively everywhere but the very top end, what i did was also put back a bit of material on the short side which picked up lower lift flow, there is still work to be done, but clearly with welding the big valve now becomes viable

the big valve previously lost out massively everywhere but the very top end, what i did was also put back a bit of material on the short side which picked up lower lift flow, there is still work to be done, but clearly with welding the big valve now becomes viable

Comment