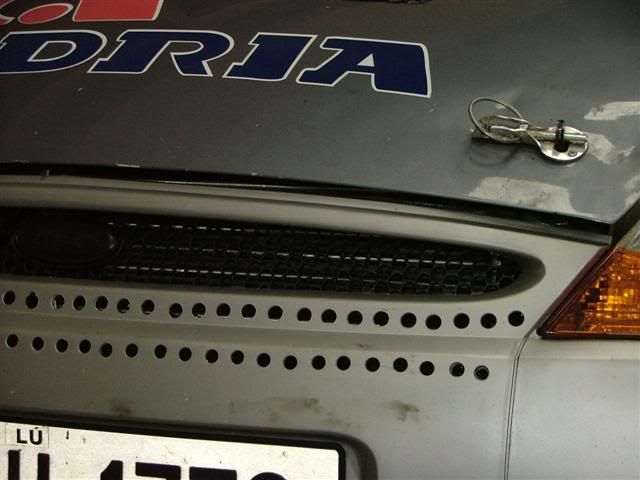

a while back will know I bought an ex -KA Challenge rally car , to go rallying. Some things a man has to do , before he gets too old...

So I'm gonna start a thread here if that's ok , see what you guys think of my tweakery , and hopefully you'll be able to suggest improvements.

So I'm gonna start a thread here if that's ok , see what you guys think of my tweakery , and hopefully you'll be able to suggest improvements.

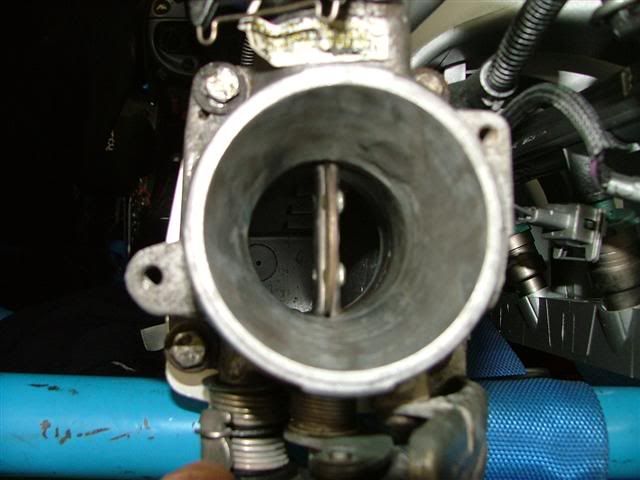

. Anyway... figured out what wires on each plug should match up with their counterparts on the other one , so broke out the Crimping Tool and connectors .

. Anyway... figured out what wires on each plug should match up with their counterparts on the other one , so broke out the Crimping Tool and connectors .

Comment