Re: Fostek's R&D department

Just found this thread, stunning work Tom, you should be really proud of this

Fostek's R&D department

Collapse

X

-

Re: Fostek's R&D department

Oh they will work! Most of the front end is designed around these calipers, I can't not use them! Most likely scenario at the moment is that we make our own wheels, or, buy some F3 wheels, but that'd mean using centre-lock hubs instead of 4-stud.... Shame

Leave a comment:

-

Re: Fostek's R&D department

Thats good news it would be a shame if you couldn't make them workLeave a comment:

-

Re: Fostek's R&D department

The wheels in the picture won't clear - I've just robbed these off my dad's car to get this thing rolling (minus calipers). The wheels I've got in mind for it will clear, only just but they will clear.Leave a comment:

-

Re: Fostek's R&D department

Looks great Tom ,are the wheels going to clear your calipers ?Leave a comment:

-

Re: Fostek's R&D department

Looking great Tom. I love the colour and the attention to detail is incredible. I think you are raising the bar for others to follow!!

I hope you bring it down to Rally Day in September as this will have as much, if not more attention than Simon & Jons new car did last year.Leave a comment:

-

Re: Fostek's R&D department

Looking fantastic Tom - hurry up and finish it!

Leave a comment:

-

Re: Fostek's R&D department

Quick update;

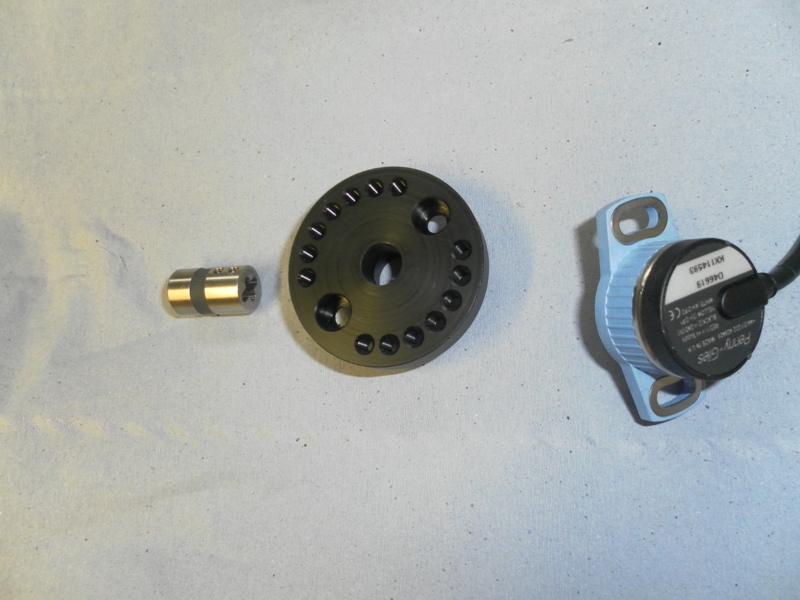

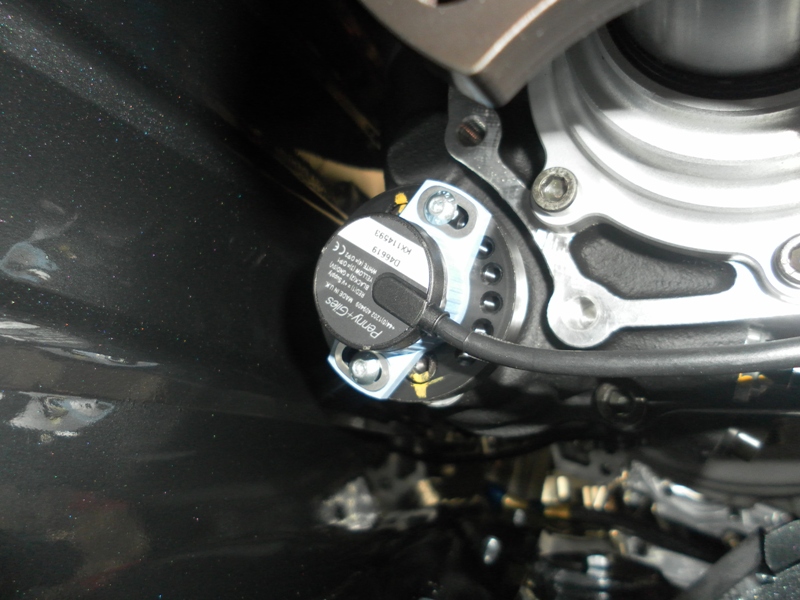

One of the most important components in the gearshift system is the barrel position sensor. The original one, that comes with the gearbox, was really only meant to be used for driving the gear display, not a gear control unit, and so it's not too accurate... So we had to replace it with a better quality, more precise sensor. Naturally, it didn't fit, so some machining and head scratching was required (thanks to CossieMatt for this) The first attempt all looked nice, but on checking the sensor was working properly, I realised it was working the wrong way round - i.e. the voltage output from the sensor was decreasing when you moved up a gear, and vice versa.... So this was the 2nd attempt; same sensor but clockwise rather than anti-clockwise.

all fitted

And I said it would have wheels!

Leave a comment:

-

Re: Fostek's R&D department

The Engineering work going into this is amazing. Going to be awesome when its done.Leave a comment:

-

Re: Fostek's R&D department

Correct, the MBE controls the gearshift. There's actually only 1 actuator on this system. Most systems use a 2nd, smaller actuator to blip the throttle on downshifts but this system is running fly-by-wire throttle (also driven by the MBE) which takes care of the throttle blips, so no need for that extra actuator.Leave a comment:

-

Re: Fostek's R&D department

I take it that the MBE is controlling all the gear actuators, as Steve uses on the Westfield sprint car? Should work well if so as its had plenty of development and seems very reliable.Leave a comment:

-

Re: Fostek's R&D department

I was stunned how quiet it was actually! Obviously you can hear it in the workshop, but with the engine running and helmet on, you can't hear the compressor. Which, incidentally, makes it all the more important that there's some safety built-in and the digi dash will give me plenty early warning that the receiver pressure is dropping (i.e. compressor has failed) If you wait until the pressure is so low it won't change gear - you're proper screwed as there's no back up mechanical linkage to change gear!Leave a comment:

-

Re: Fostek's R&D department

No, I did mean 300bar, as in 4500psi.

Not withstanding any air leaks, the bottle will give approx 1200 - 1400 gearshifts on one fill, depending on actual working shift pressure, which is still TBC (won't know until we test it) This might come as a surprise, but even with a 6-speed clicky box and short ratios, you're very unlikely to average more than 25 gearshifts per mile - and that's on a very tight twisty stage. Most close-road type stages will see 18-20 shifts per mile max. So you can do some maths; that's a fair old milage from 1 fill.

The bottle is a Mil-spec carbon/kevlar job, it's literally bulletproof (I should mention that the bottle I'm talking about charging to 300bar is not the one in the pictures, which is a paintball bottle - still 300bar mind). I'm not worried about the bottle rupturing in a crash; if the crash is big enough to rupture the tank (or indeed break off the HP reducer) then the air is the least of your worries.Leave a comment:

-

Re: Fostek's R&D department

Peter - just so happens I can help you with this - the man you need to speak with is a Mr J Edwards as in JEMS, Daventry, i think you know of him!? The front suspension kit is JEMS work, and the rear end 4-link geometry.Leave a comment:

-

Re: Fostek's R&D department

its not a bomb,its a rocket launcher ,looks good tom

,looks good tom ,are you going to cover the compressor to soundproof it,will make a racket in the cabin

,are you going to cover the compressor to soundproof it,will make a racket in the cabin

Leave a comment:

Leave a comment: