Re: Fostek's R&D department

Thanks for that interesting news, look forward to reading more as and when.

Fostek's R&D department

Collapse

X

-

Re: Fostek's R&D department

Not that I'm aware of. There are alloy axles in existence (see my Facebook page) but not in Historic rallying.

The axle for this car is pretty special; Magnesium diff housing, titanium LSD, chromoly tubes, it is unique and not something available to customers at the moment. I'll start a thread just for the axle when I get round to assembling it...Leave a comment:

-

-

Re: Fostek's R&D department

Power is nothing without Traction, Audi discovered that in 1979 and 80 with Rallying.

It looks a Beautiful Car and an interesting Build. I have heard rumors that there are Alloy Axle casings that are about on some historic Escorts.Leave a comment:

-

Re: Fostek's R&D department

Interesting build, looks mint already, very nice and I like the bolt on panels

About 2.5 vs 2.0, we have lots of 2.5 over here class 14 and tons of 2.0 16V class 13, I am not sure if there are minimum weights over here but here is my take on 2.5 vs 2.0 in Ireland

On dry tarmac 2.5 is by far the fastest, 2.0 just cannot compete on the straights, But with 2.5 there is also a big advantage out of corners, they power away like a bat out of hell, as for top speed, I doubt that any of the mk2's are getting much over 120mph on the long straights (there are very few straights like this in most rallies)

In wet or even slightly damp conditions 2.5 is a disadvantage imho, 1.6 to 2.0 cars do far better in these conditions, trying to put 300bhp and big torque down to a wet road is a big challenge

Your weight penalties may change this a lot making the two classes very close together with both cars close to the minimum weight

The 2.5 engines do not produce a massive amount more top end bhp but the big advantage is mid range torque imho which is very noticeable

Having said all of that driver skill makes a far bigger difference than all of the above, the difference between a very fast driver and an average one is night and day and in the right hands a mk2 with a proper 2.0 16V engine can win at almost any rally

If it was a straight up drag race 2.5 would win for sure but rallying does not compare to this, 70kg is a lot of weight on each corner and with 6 speed the 2.0 will be ready to go out of every corner

Best of luck with it and sure it is going to be a real contender in the overall MK2 results

Leave a comment:

-

Re: Fostek's R&D department

Cheers for the comments fellas,

and thanks for the editing Dave - no idea why it did that??

Anyway, couple more pictures for you from this morning;

Front panelwork is now on for good. The wings, arches, spoiler, front panel and slam panel were all painted off the car and are now bolted-on rather than welded. Apart from anything, it makes installing the engine (well, everything in the engine bay) easier with the panels off, and it means the paint sprayer could do a more thorough job of painting those parts you'd miss if all the panels were on. It looks a bit OTT but I wanted to retain the sort of strength/rigidity that the original spot welds provided. There's about 120 bolts holding the front end together! Don't worry, they are all Aluminium bolts (m4 thread) so weight is negligible. If the car is ever in a prang (pretty likely) then it should just be a case of replacing a panel, no need for taking the whole car to a bodyshop.

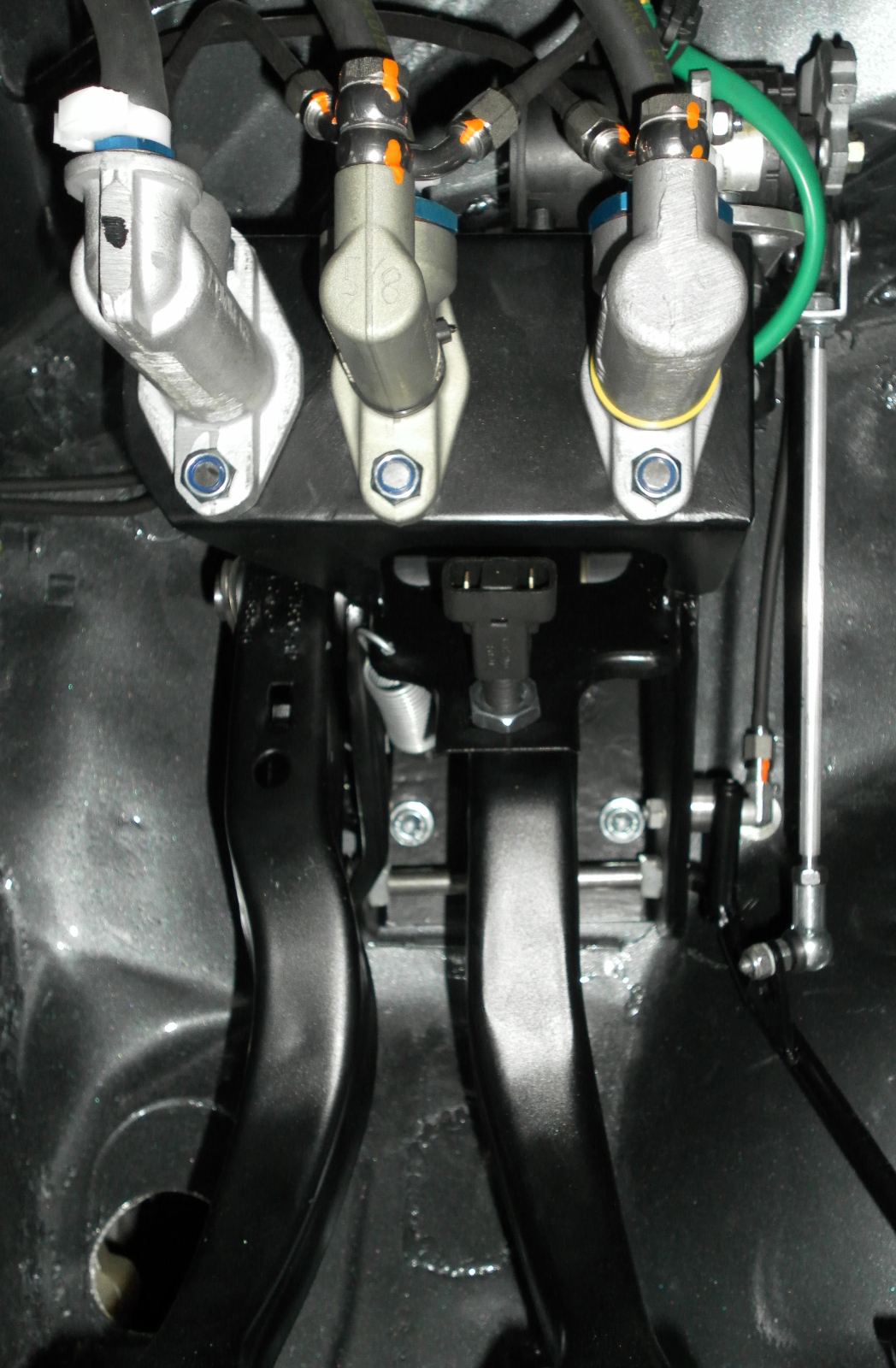

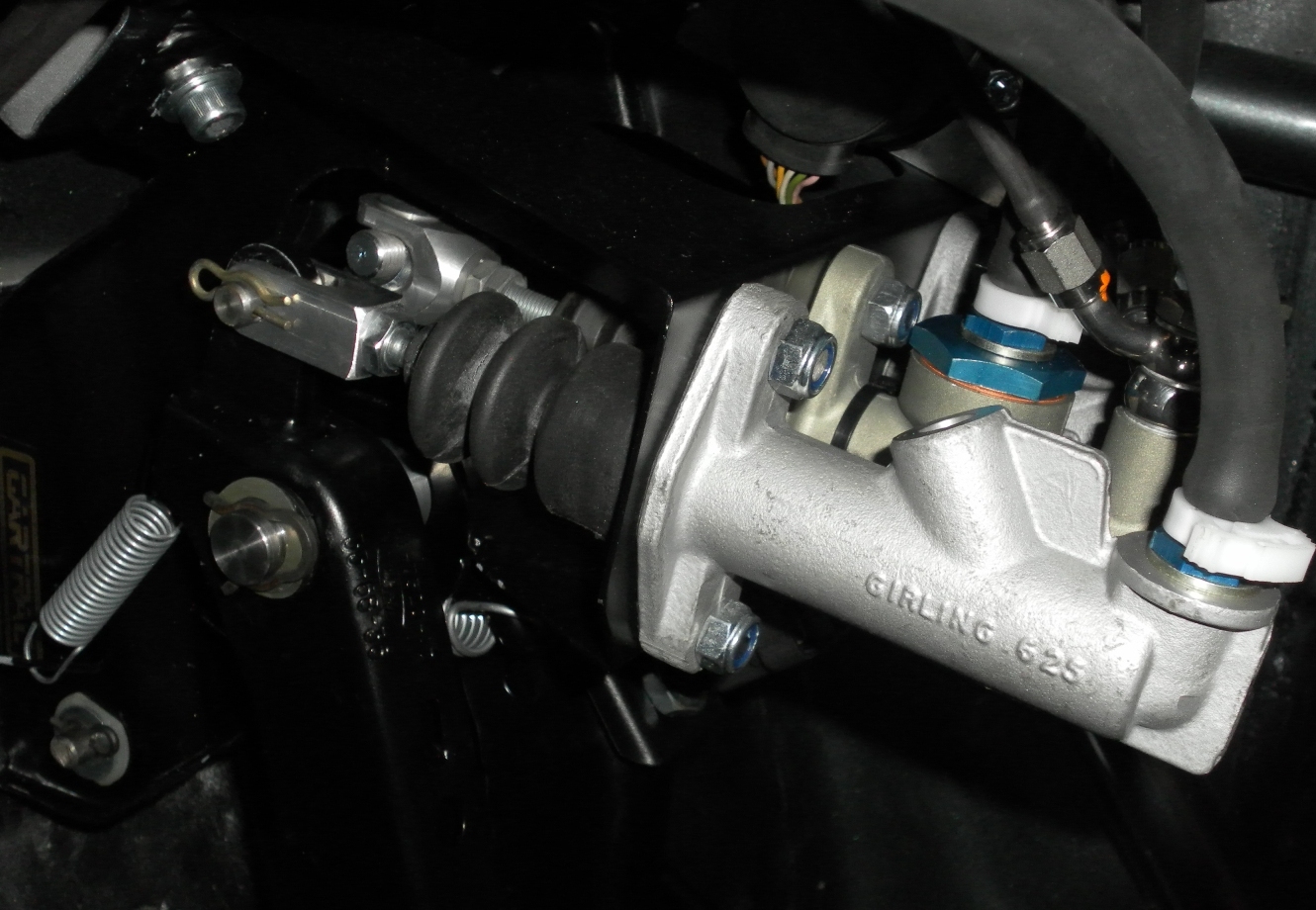

Pedal box and brake plumbing is all in for good. The pedal box is a good old fashioned Gartrac job, although it has had the Fostek treatment and is now stiffer & lighter. I did look into using floor mounted pedals, but it just won't work for us, ergonomically, so it had to be underslung like the standard box. To be fair, the Gartrac job is brilliant, I love the thought and design work that has gone into them, and they work very well. I've gone for AP master cylinders rather than the normal Girling type, partly due to them offering better pedal feel, but also because they have a much bigger choice of sizes/bores which can be handy for fine-tuning the hydraulic system. The clutch cylinder is standard issue Girling job, not too fussed about that, it's only used for getting the car off the start line.

One thing worth mentioning, (and this was an idea I got from Andy Pipe's TS thread) is that I actually fully plumbed/bled/setup the braking system on the bench prior to fitting in the car. I reckon one of the biggest causes of unsatisfactory brakes in a competition car is the pedalbox either being badly built, or just not set up properly. There is a lot can go wrong! By doing it on the bench, I was able to bleed the whole system and piss-fart around with master cylinder pushrod lengths, bias bar float, pedal height etc etc - the idea being that you want the bar itself 90 degrees to the pushrods when it's under pressure. This invariably means the bar will sit slightly skewed when at rest, but that's fine. This sort of fine tuning is just a pain in the arse when the box is in the car! Another thing I noticed (might be obvious to some people, but I'd never noticed before) was that it was just not possible to PROPERLY bleed the system unless I opened a front and rear bleed nipple at the same time. If you just opened 1, it would seem to bleed ok, except what was actually happening was that 1 MC was running out of travel before the other (only just, but it would be enough to trap air). That's just the sort of thing you wouldn't spot with the system in-situ. So once happy the pedalbox was setup properly, it was all fitted up... Apart from adjusting the front>back bias, it shouldn't need touching now.

The throttle pedal looks a bit strange - and that's cos it is. We're using SBD's new fly-by-wire throttle system, so the pedal itself is now really just a sensor, telling the ECU what the throttle demand is, and the ECU then decides how far to open the actual throttle. That's a little aluminium rose-jointed link connecting the pedal to the throttle pedal position sensor mounted on top of the pedal box....

The brake lines are a bit different too. I've never been a fan of running braided Aeroquip type hose throughout the car; just no point (although it is simple) - I'd rather use solid lines everywhere apart from those bits that actually need to flex... So what you can see here is a bit of a concoction of Goodridge stainless fittings, banjos etc and good old fashioned kunifer pipe, with some black heatshrink over the top to make it look neat.

I discovered an INCREDIBLE method for straightening the kunifer pipe (wibbly wobbly brake lines are my pet hate) - it involves a vice, mole grips, and a big hammer - check this out: http://www.youtube.com/watch?v=LvGEKaaPf5E

Hydraulic handbrake base is in, although it needs mounting properly. I wasn't going to bother with a hydraulic handbrake at all (what's the point?) but the driver of this car convinced me to fit one; purely to get him out of trouble if he over-shoots a corner, not that it's used for actually getting round tight corners... Modern diffs and EPAS did away with the need for handbrake turns...

That's all for now, keep watching Last edited by FOSSIE; 30-12-2013, 12:10.

Last edited by FOSSIE; 30-12-2013, 12:10.Leave a comment:

-

Re: Fostek's R&D department

I was think of grey for my build and now I have see a mk2 escort in grey it looks the nutsLeave a comment:

-

Fostek's R&D department

Nice to see it in paint Tom.

Fingers crossed that low front spoiler doesn't cause to many issues out on the Tarmac on 13'sLeave a comment:

-

Re: Fostek's R&D department

Love it, love it, love it!! That is a gorgeous colour Tom.

I will be interested in the JEMS wide track, as i am thinking of going down this route next.

Just got back from Longmoor today and Pete Rayner was there with his new Millington 2+ and for the first 3 stages, even on the wet map, he just could not get the power down. His son was winning at the end of stage 3 due to the frost/ icey tar in his 1400 Citroen AX, and Pete was down to about 7th. Not belittling Petes engine by any means, but now you can't get Dunlops any more either, i will be interested to see what the choice of tyre will be without having to go all out on Michelins next year.

Keep the updates coming please Tom.

Leave a comment:

-

Re: Fostek's R&D department

there is certainly merit in your logic of not going to 2.5, my limited knowledge of rallying say you may well be right, certainly on the circuits lighter smaller engined cars can give the bigger ones a real hard time and only really loose out on the very fast long circuits, where a lot of power results in very high top speed, but my limited knowledge of rallying is that you dont have straights long enough to reach 130 plus mph speeds where a 2.5 would come into its own.Leave a comment:

-

Re: Fostek's R&D department

I too share your take on fast cars. Bigger is not always faster. Only, instead of 2,0 against 2,5's I run 1,6 against 2,0. And to some extent I can tell the consept does work it's far from superior but defenately competetive. I believe with a smaller cc engine you have two main advantages. Weight and weight distribution.

Oh and that car Is to die for! Best of luck with it.Leave a comment:

-

Re: Fostek's R&D department

Looking good Tom.

i edited it for you, hope it is OK at that.

Leave a comment:

-

Re: Fostek's R&D department

Simply stunning and no surprise judging by the standard of work Fostek are known for , looking forward to the updates

Leave a comment:

-

Re: Fostek's R&D department

Sure to be the best Escort in the country once it's finished.....I don't know anybody else who puts so much thought and effort into their build

Leave a comment:

Leave a comment: