Here at Fostek, a large proportion of our time goes into developing new products, and also making current products lighter, stronger, perform better, last longer, etc. So it's only sensible that we invest some time and money into building a suitable test bed for, err, testing things, prior to selling them. OK, it happens to look a bit like a mk2 Escort, but that's besides the point.

These days, if you want to build a mk2 to be quick on Tarmac, it will tend to follow a tried and tested pattern; a big CC engine, Tractive box, 15" wheels, heavy duty rear end etc. Not that there's anything wrong with all that, it sure makes a quick car, but I fancied approaching things from a different angle. First up is weight. There's rules to govern how light the car can be for rallying; the 2.5's have a MIN weight of 890kgs (not that many are even remotely that light). A 2L mk2 has a MIN weight of 820kgs, quite a handy amount less. And also, by running a big CC engine, you tend to have to up-armour the rest of the car - big old gearbox to take the torque, heavy duty axle, prop, brakes, etc etc. AND, what a lot of people forget is, that a big CC engine tends not to rev like a smaller engine.

So to achieve a similar top speed, you'd have to gear a 2.5 motor higher than a 2L, for example. Not only that, but I suspect (I have to say that, because I'm not a driver) that very, VERY few drivers will be able to make the most of kind of power a 2.5 puts out. Especially on 8" wide rear wheels...

Perhaps the extra grunt of a 2.5 is just a hindrance on anything other than smooth, dry, grippy tar? Anyway, I did some maths, and I reckon that if I can get this car down to it's legal minimum weight, it will have comparable power-to-weight ratio of the 2.5s, but given it's 100kgs ligher, it'll handle better and stop better, amongst other things.

Not only that, because of the high revving engine, and 6 close gears, the gearing can be VERY short. And I can run lighter duty axle, prop, clutch, and brakes.... So that's the plan anyway. We shall see!

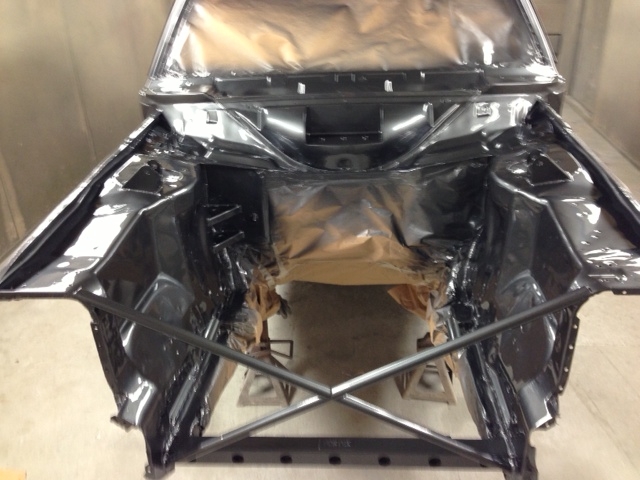

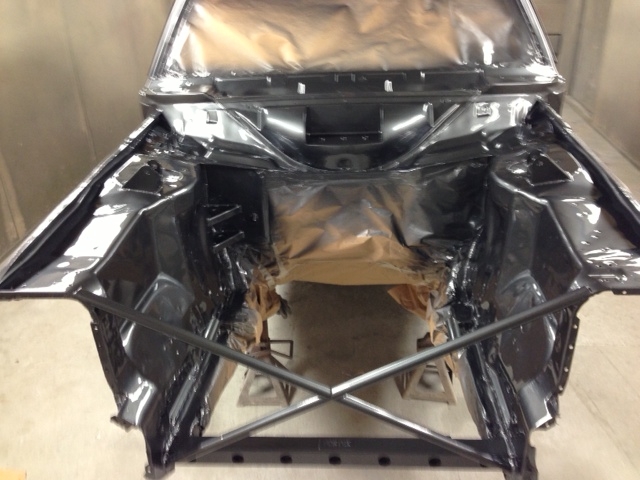

It's taken about 4 years to reach this point; I'll not bore you with all the fabrication/bare shell pictures - given that this car is going to compete in National Tarmac Stage rallying, the bodyshell has to meet a fairly strict set of rules in terms of what you can/can't do to it, cut out, replace etc. So by mk2 Escort standards, it's not that trick, good old fashioned engineering here. The pictures start with the shell in the paint booth...

.JPG)

I actually started with a semi-prepared shell; It had been built to Historic Spec (BDG, ZF etc) for Alister McRae to use in the BHRC a few years back, but for one reason or another that never happened. It had already had the cage fitted, tunnels, 4-link boxes etc. The tunnel needed modifying because I wasn't likely to use a ZF box in such a modern car, likewise we made a few tweaks to stiffen it up, remove some weight, and distribute weight as carefully as possible. Exhaust tunnel was also in the wrong side, so rather than cutting it out, I just mirrored it, so there's now twin tunnels, which a) adds rigidity to the floor and b) means you could run a different engine later if you fancied...

Again, externally, no need to re-invent the wheel. Rear arches are Gartrac boreham jobs, fronts are also Gartrac but +1" each side to cover the JEMS wide track front end (more of that later) and the front spoiler was made specially to include some ducts, in an attempt to keep the front brakes from melting. The colour is Jaguar Gun Metal Grey in case you are interested.

Engine: pretty obviously a SBD Duratec, not just any one though, this is Matt Downer's old engine, and prior to that, an SBD test mule. I've had the pleasure of sitting next to Matt on several rallies, and thus I didn't need any convincing that this engine is more than capable of taking on any other 4-pot N/A engine currently on the market.

This is the engine in a previous home: http://www.youtube.com/watch?v=vo-TVyMdEgo

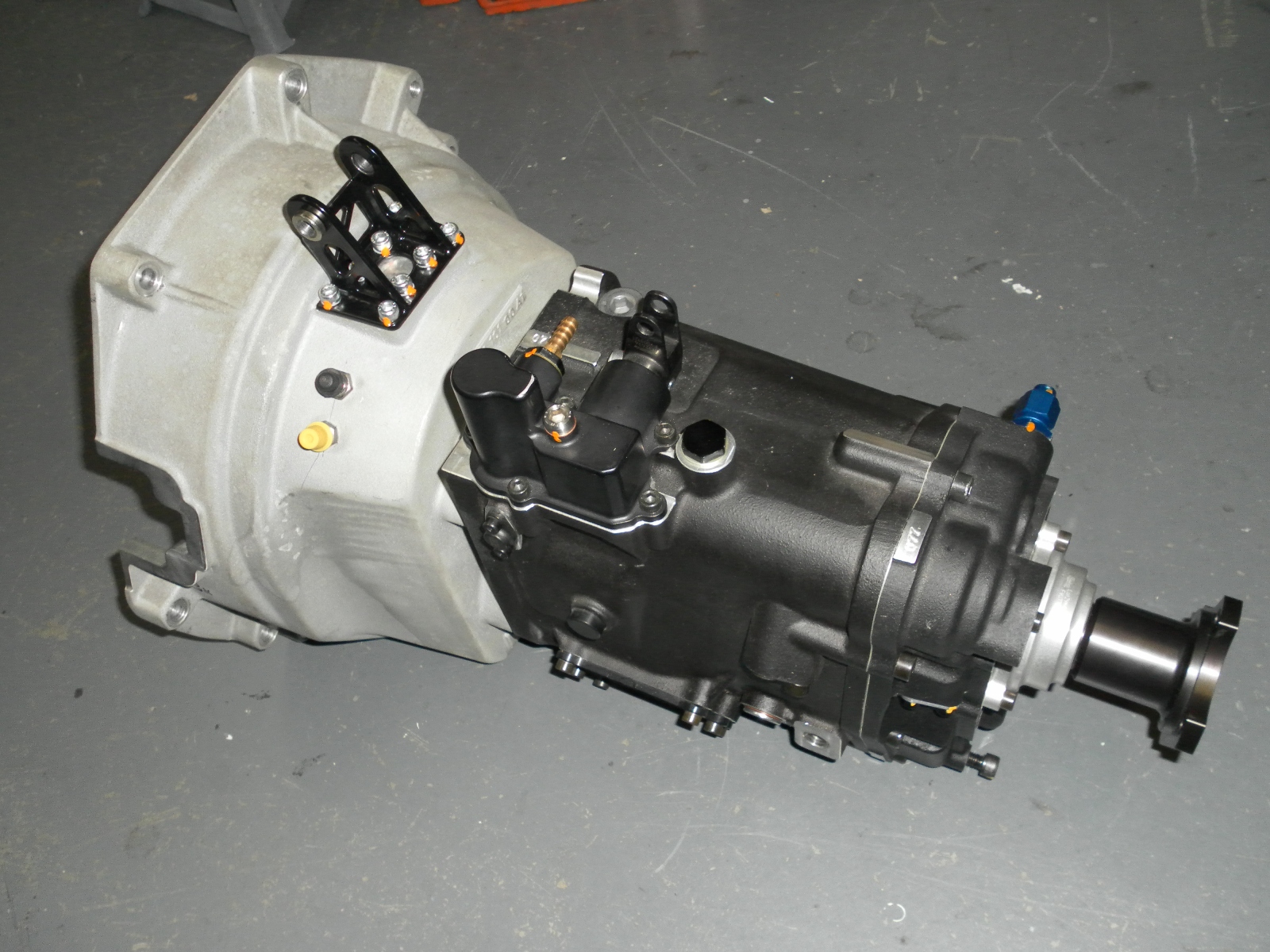

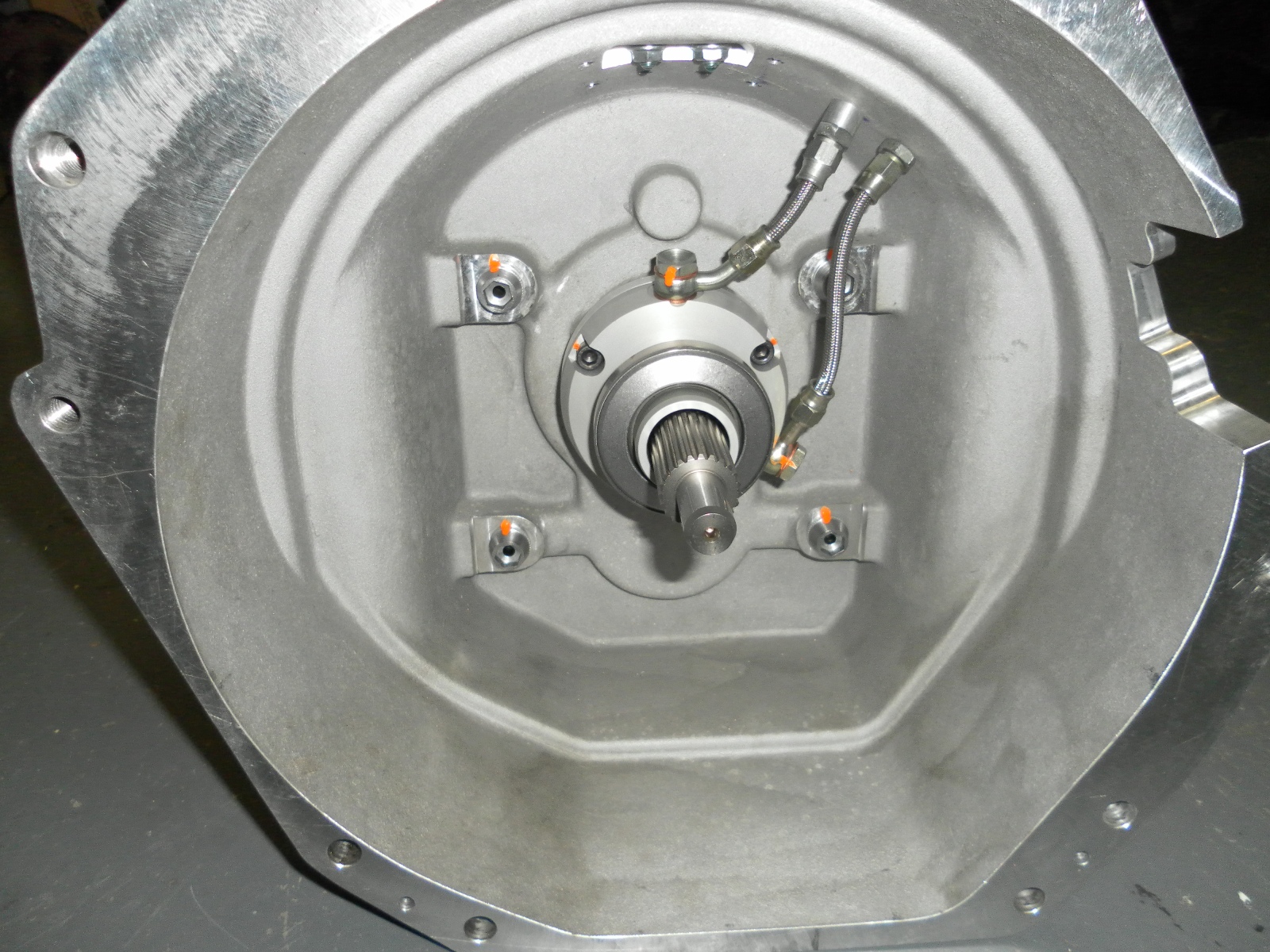

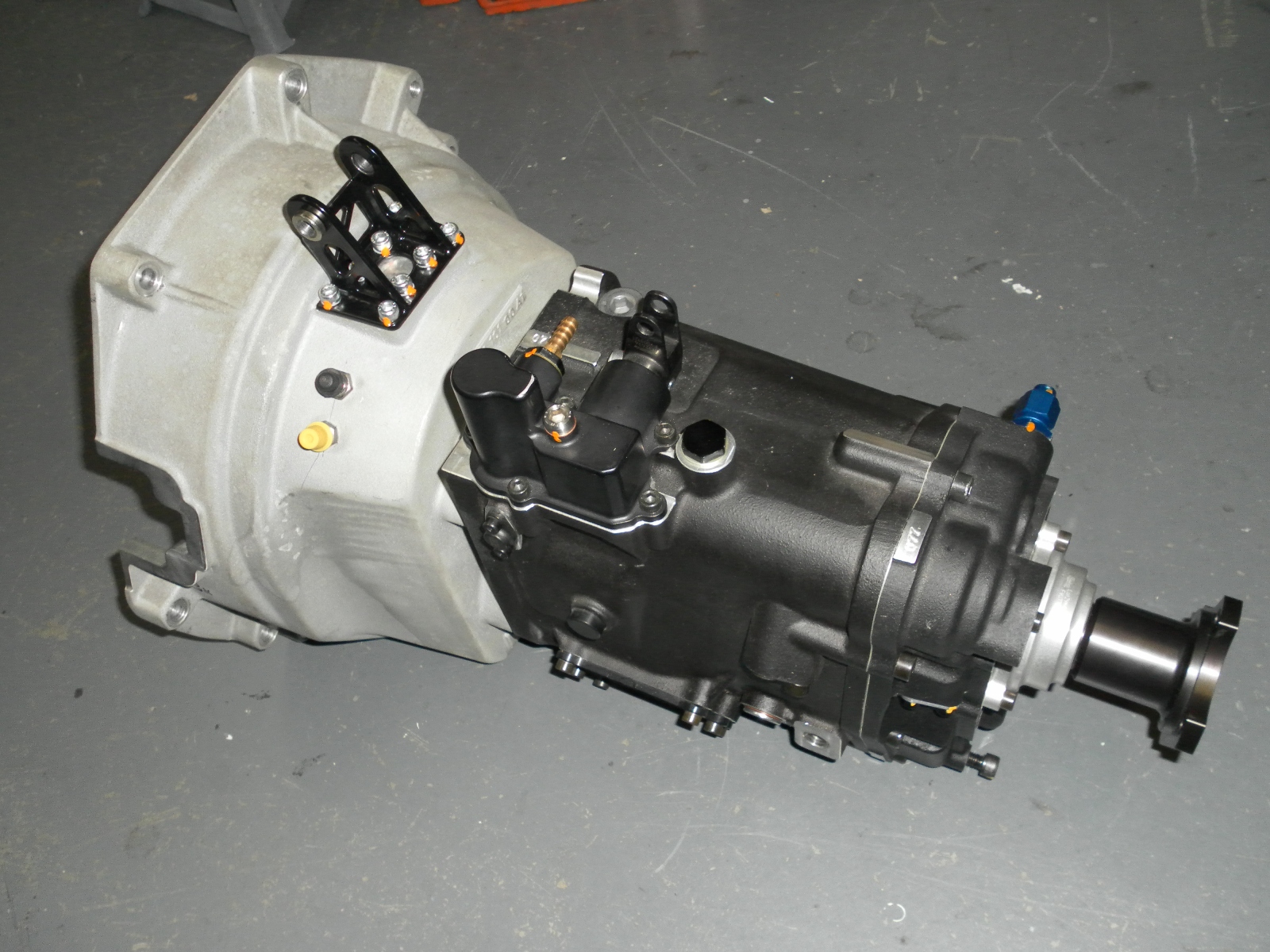

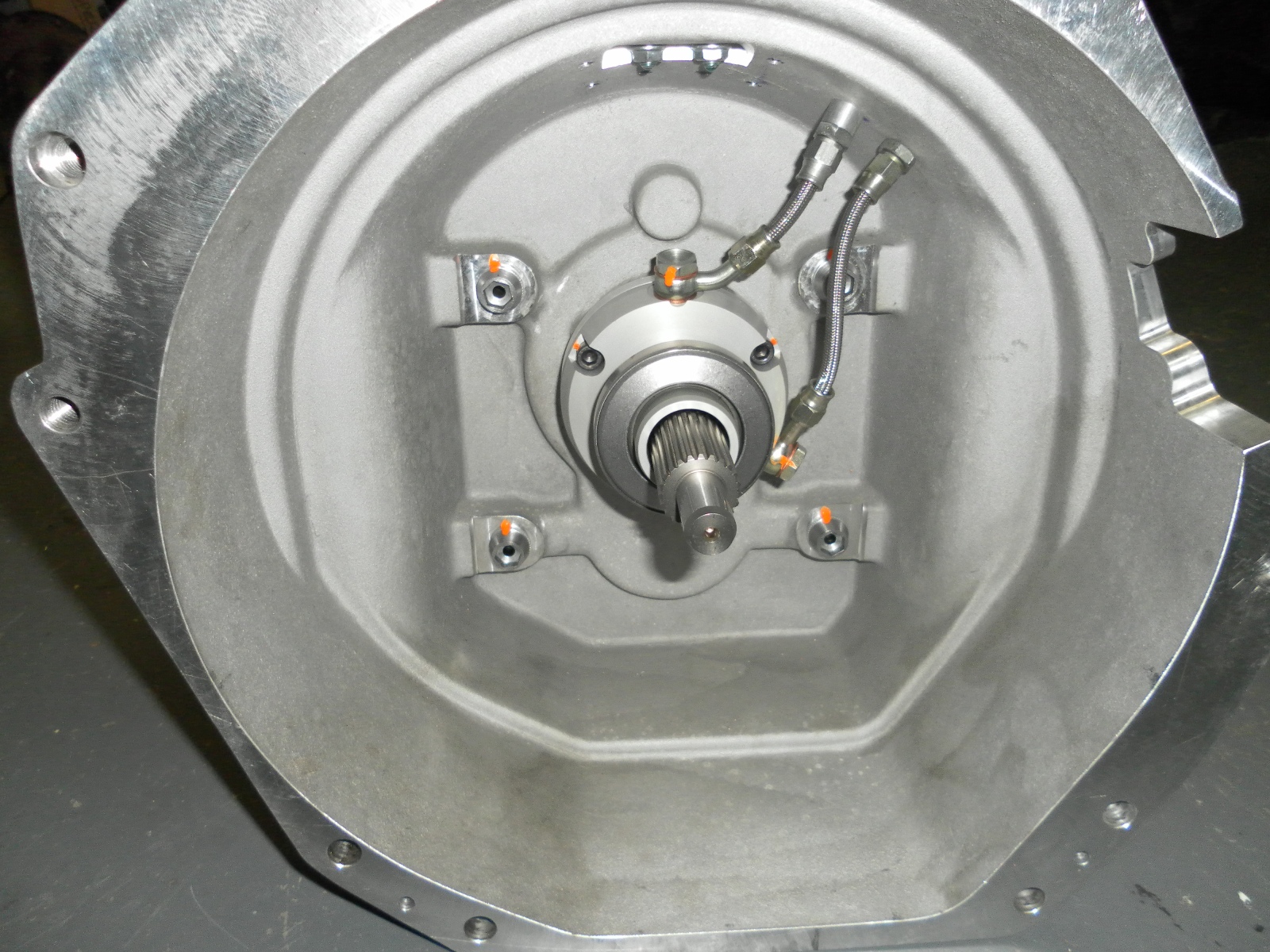

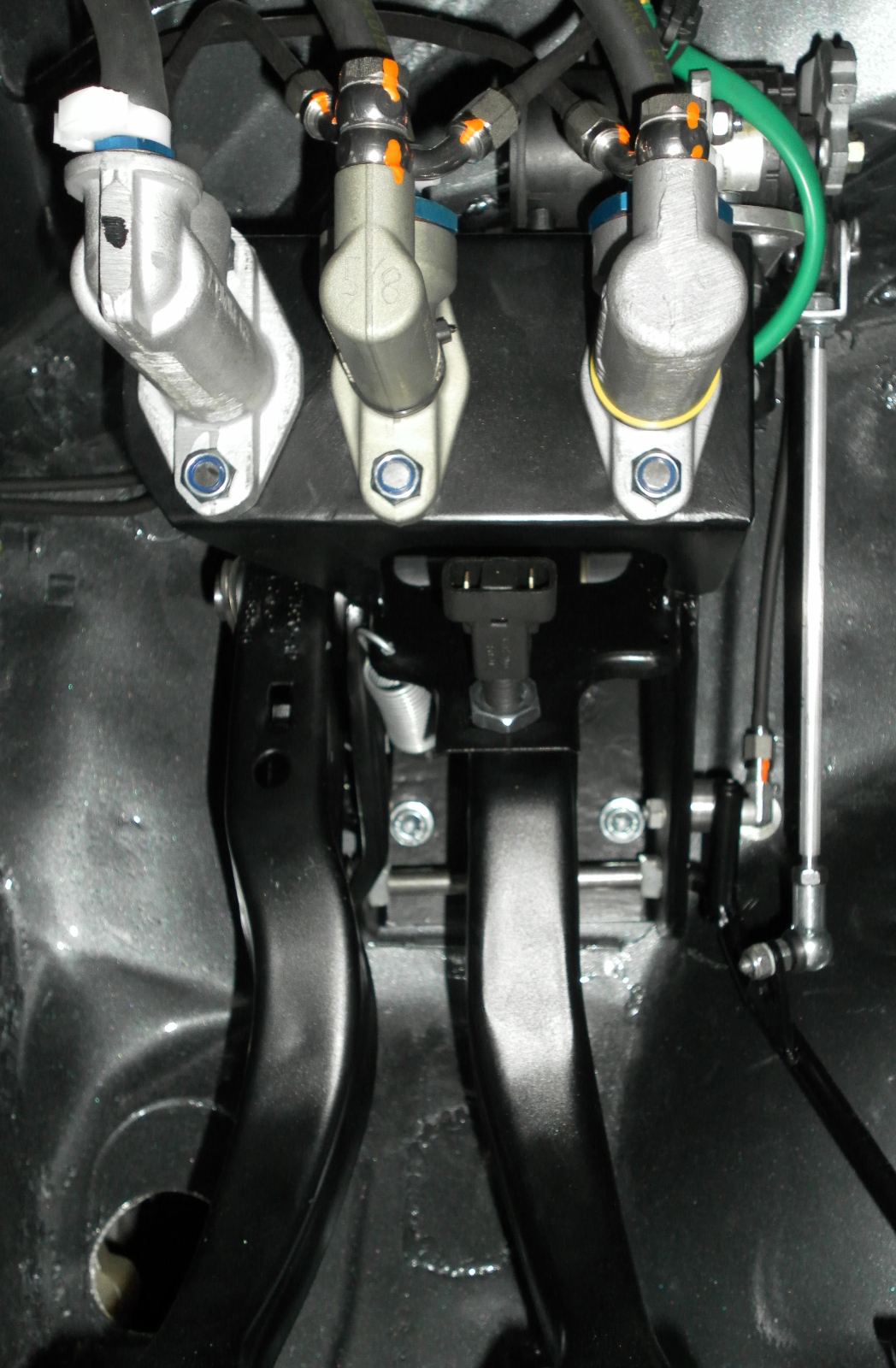

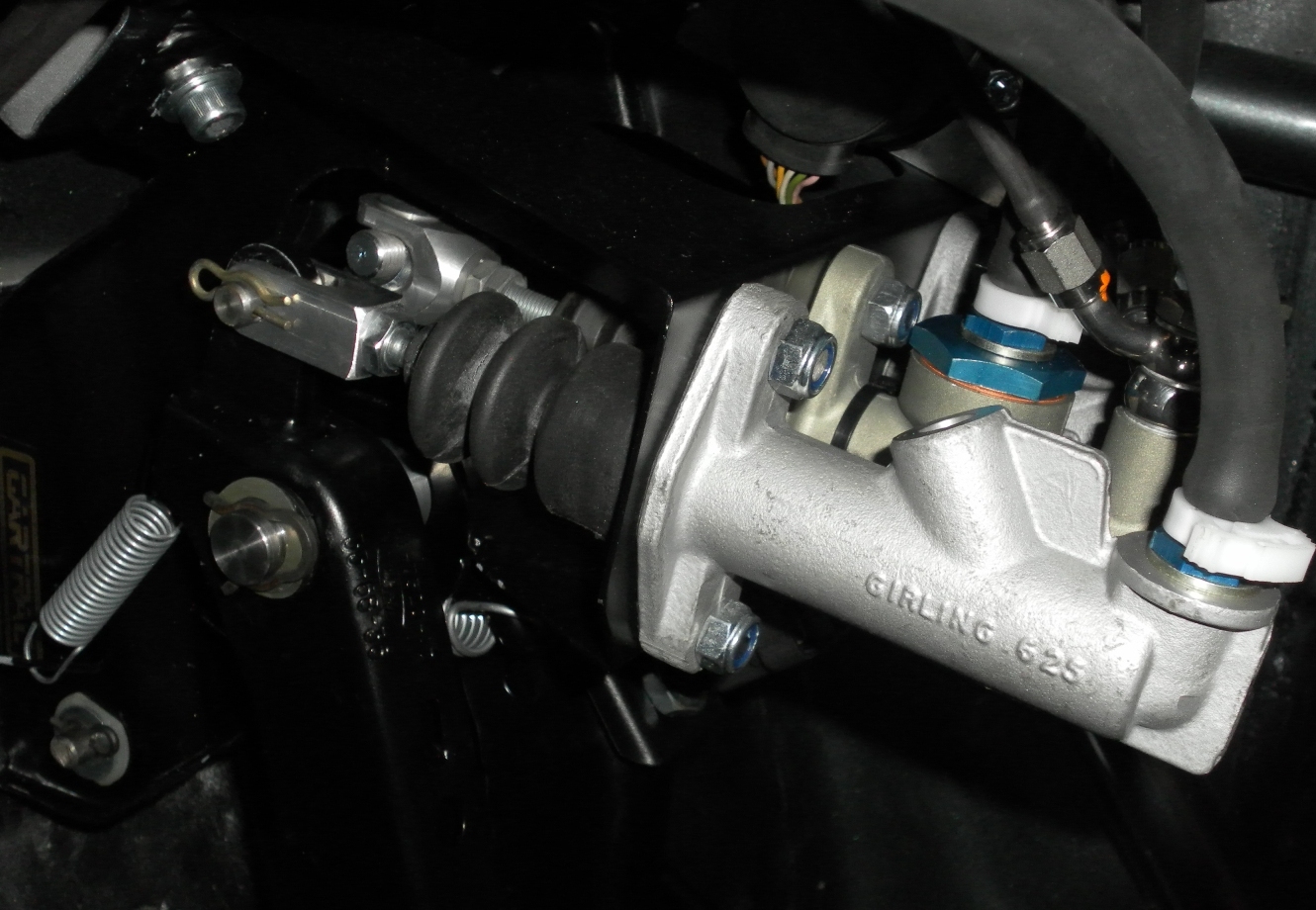

Mated to this is a Sadev 6-speed sequential. Chosing a gearbox wasn't easy, but this thing ticks all the boxes for me. No need for a gearstick, some compressed air and electrickery takes care of chanaging gears. That's all for the moment; more photos as the build progresses...

These days, if you want to build a mk2 to be quick on Tarmac, it will tend to follow a tried and tested pattern; a big CC engine, Tractive box, 15" wheels, heavy duty rear end etc. Not that there's anything wrong with all that, it sure makes a quick car, but I fancied approaching things from a different angle. First up is weight. There's rules to govern how light the car can be for rallying; the 2.5's have a MIN weight of 890kgs (not that many are even remotely that light). A 2L mk2 has a MIN weight of 820kgs, quite a handy amount less. And also, by running a big CC engine, you tend to have to up-armour the rest of the car - big old gearbox to take the torque, heavy duty axle, prop, brakes, etc etc. AND, what a lot of people forget is, that a big CC engine tends not to rev like a smaller engine.

So to achieve a similar top speed, you'd have to gear a 2.5 motor higher than a 2L, for example. Not only that, but I suspect (I have to say that, because I'm not a driver) that very, VERY few drivers will be able to make the most of kind of power a 2.5 puts out. Especially on 8" wide rear wheels...

Perhaps the extra grunt of a 2.5 is just a hindrance on anything other than smooth, dry, grippy tar? Anyway, I did some maths, and I reckon that if I can get this car down to it's legal minimum weight, it will have comparable power-to-weight ratio of the 2.5s, but given it's 100kgs ligher, it'll handle better and stop better, amongst other things.

Not only that, because of the high revving engine, and 6 close gears, the gearing can be VERY short. And I can run lighter duty axle, prop, clutch, and brakes.... So that's the plan anyway. We shall see!

It's taken about 4 years to reach this point; I'll not bore you with all the fabrication/bare shell pictures - given that this car is going to compete in National Tarmac Stage rallying, the bodyshell has to meet a fairly strict set of rules in terms of what you can/can't do to it, cut out, replace etc. So by mk2 Escort standards, it's not that trick, good old fashioned engineering here. The pictures start with the shell in the paint booth...

.JPG)

I actually started with a semi-prepared shell; It had been built to Historic Spec (BDG, ZF etc) for Alister McRae to use in the BHRC a few years back, but for one reason or another that never happened. It had already had the cage fitted, tunnels, 4-link boxes etc. The tunnel needed modifying because I wasn't likely to use a ZF box in such a modern car, likewise we made a few tweaks to stiffen it up, remove some weight, and distribute weight as carefully as possible. Exhaust tunnel was also in the wrong side, so rather than cutting it out, I just mirrored it, so there's now twin tunnels, which a) adds rigidity to the floor and b) means you could run a different engine later if you fancied...

Again, externally, no need to re-invent the wheel. Rear arches are Gartrac boreham jobs, fronts are also Gartrac but +1" each side to cover the JEMS wide track front end (more of that later) and the front spoiler was made specially to include some ducts, in an attempt to keep the front brakes from melting. The colour is Jaguar Gun Metal Grey in case you are interested.

Engine: pretty obviously a SBD Duratec, not just any one though, this is Matt Downer's old engine, and prior to that, an SBD test mule. I've had the pleasure of sitting next to Matt on several rallies, and thus I didn't need any convincing that this engine is more than capable of taking on any other 4-pot N/A engine currently on the market.

This is the engine in a previous home: http://www.youtube.com/watch?v=vo-TVyMdEgo

Mated to this is a Sadev 6-speed sequential. Chosing a gearbox wasn't easy, but this thing ticks all the boxes for me. No need for a gearstick, some compressed air and electrickery takes care of chanaging gears. That's all for the moment; more photos as the build progresses...

Comment