Fostek's R&D department

Collapse

X

-

Re: Fostek's R&D department

Thats good news it would be a shame if you couldn't make them workComment

-

Re: Fostek's R&D department

Oh they will work! Most of the front end is designed around these calipers, I can't not use them! Most likely scenario at the moment is that we make our own wheels, or, buy some F3 wheels, but that'd mean using centre-lock hubs instead of 4-stud.... Shame

Comment

-

Re: Fostek's R&D department

Well I had a spare few minutes last night and given the car has, at last, got some wheels on, I couldn't resist dropping it on the corner weight scales just to see if all this effort and money has been worth it....

The result was pretty much what I'd been hoping for:

There's still plenty kit to go in the car yet, I've added up as much as I can, weighed the doors, bonnet, boot, loom, sump guard, seats etc, I reckon (give or take) there's 100kgs of equipment still to go in before we can get a true reading.

So the next big engineering challenge is safely mounting 100kgs of ballast!!Comment

-

Re: Fostek's R&D department

Well the car is due to go away for the wiring loom later this week. I've already missed the first 2 deadlines, so this time I was determined not to let the deadline slip...

It's really just been a case of getting the last few bits and pieces are hardware in place, well anything that's got anything to do with the car's wiring anyway.

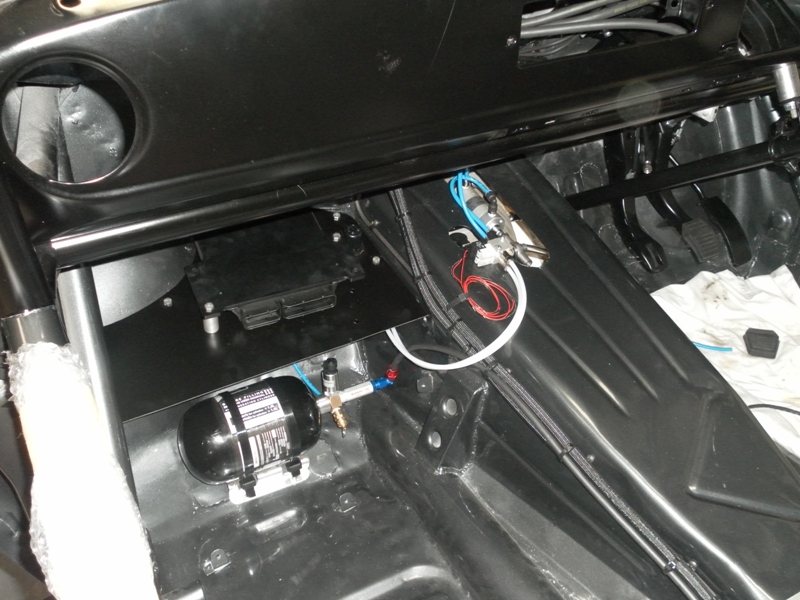

The pneumatics for the gearshift system are all now in place. We've had it running on the bench, all seems OK, but until it's connected (and driven) by the ECU then I can't say how effective it is. I forgot to get a picture of the manifold internals before it went together... Basically, that brass hex-shape fitting in the end of the bottle has a dip-stick (aka debris-tube) in one end that pokes down inside the bottle. This separates the warm air coming from the compressor, swirling it around the bottle and dumping moisture, allowing the cool(er) air to exit... This just means that when the system is working hard, you won't get warm air from the compressor by-passing the accumulator and straight to the valves. May be a bit over-kill but the theory is nice. Anyway here's the system in place. The box around the air system doubles up as a nice shelf for the ECU. There will be a front on this box, which will double-up as a footrest, but I'm leaving it off for now to give access for wiring/setting up.

Mounted the front damper reservoirs on some big cable-tie saddles. Simple enough looking job but actually harder than it looks, you want to allow free movement in both directions of the banjo. That sensor (cable tied to the damper hose) is the inlet air temp sensor; haven't decided where that's going yet so it's in the "too hard box" for today.

Here's the view from driver's seat. The whole steering wheel/joystick assembly is a mock-up for now, no point spending too much time on it until we've driven the car and review the driving position and general ergonomics of it all. The joystick is just hung on some gash tube for the moment; eventually it'll have a proper bracket but no point doing that until we confirm where it needs to go. I suspect it'll need to be a bit lower, and a bit further forward than it currently is.

The clutch pedal is in bits whilst I fit the various sensors which initiate the launch control and some other stuff. That should have been done today but apparently it's a bank holiday or something and nowhere is open (need some fluid to bleed the system first)

Oh and I mounted the horn too, not very exciting, but one of those "suppose I'd better fit one" jobs; nice little PIAA slimline thing off eBay that's slotted down behind the front panel next to headlight bowl, out the way.

Getting there!Comment

-

Re: Fostek's R&D department

Taking a mk2 to the next level wicked car, if you need more cooling on them front brakes you could turn the bells round, build spec is extremely top notch wicked car

Comment

-

Re: Fostek's R&D department

Hi chaps.

Sorry for the lack of updates but due to the major changes at Fostek we haven't had time to update this thread or do much to the car.

The workshop is now sold so I had to get the car mobile to rehouse it ... and before you start shouting, YES it's on 15" wheels but that is only for rolling it about. It will have 13" wheels on when we find the right ones.Comment

Comment