Re: Fostek's R&D department

Sounds like a bag of spanners!

It's a big relief now the shift system is playing ball. What a headache that's been. Although it did 'work' straight out the box, it wasn't quite right. It was quick, way quicker than you could achieve by pulling a lever by hand, but clearly something wasn't right. These Sadev units require a relatively high force to move the linkage, not only that but the force ramps up quickly due to high spring rates in the barrel detent mechanism, and cam design. The fact that the mechanism started moving quickly when you fired the air cylinder, but then rapidly slowed down, was occasionally confusing the electronics.

More force was needed! Fitting a bigger bore cylinder and/or higher operating pressure is easy, but you need to match the solenoid valves to the rest of the system... Finding valves of the right format, quality, flow capacity - importantly - switching speeds was a bit tricky. Most of the paddle shift systems on the market uses solenoid valves which are slow to switch on. Typically 40-50mS. That means when you press the button to demand a shift, nothing happens for the first 40-50mS whilst it waits for the solenoid to turn on the air, then the mechanism starts to move... I want the whole shift to happen in less time than that! Fast switching valves are generally either 24v, or very small (restrictive) or both. Anyway, the valves currently in there have a switching speed of sub 1mS, and although they are theoretically a bit small, the shifts are superb. Quicker than Sadev though possible!

Anti roll bar is fitted, bit of a guess at what rate is required so I've gone with something at the softer end of the scale. Easy to swap for stiffer tube if required.

Not sure what's next actually. Probably time to freeze development and get some use out of it!

Sounds like a bag of spanners!

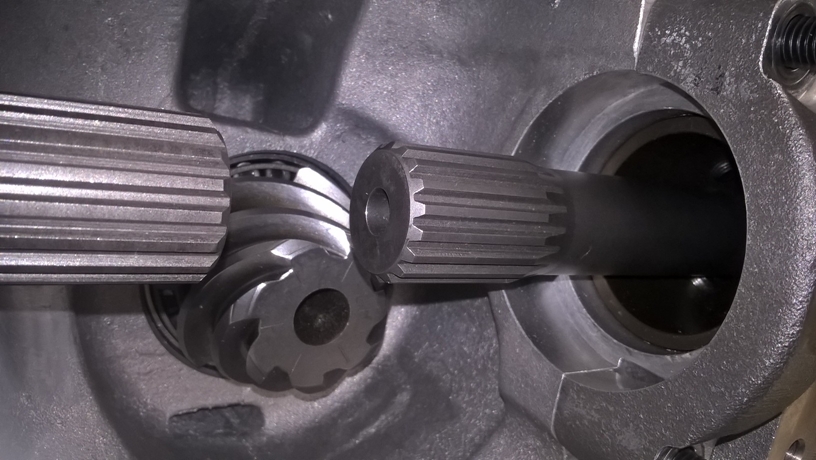

It's a big relief now the shift system is playing ball. What a headache that's been. Although it did 'work' straight out the box, it wasn't quite right. It was quick, way quicker than you could achieve by pulling a lever by hand, but clearly something wasn't right. These Sadev units require a relatively high force to move the linkage, not only that but the force ramps up quickly due to high spring rates in the barrel detent mechanism, and cam design. The fact that the mechanism started moving quickly when you fired the air cylinder, but then rapidly slowed down, was occasionally confusing the electronics.

More force was needed! Fitting a bigger bore cylinder and/or higher operating pressure is easy, but you need to match the solenoid valves to the rest of the system... Finding valves of the right format, quality, flow capacity - importantly - switching speeds was a bit tricky. Most of the paddle shift systems on the market uses solenoid valves which are slow to switch on. Typically 40-50mS. That means when you press the button to demand a shift, nothing happens for the first 40-50mS whilst it waits for the solenoid to turn on the air, then the mechanism starts to move... I want the whole shift to happen in less time than that! Fast switching valves are generally either 24v, or very small (restrictive) or both. Anyway, the valves currently in there have a switching speed of sub 1mS, and although they are theoretically a bit small, the shifts are superb. Quicker than Sadev though possible!

Anti roll bar is fitted, bit of a guess at what rate is required so I've gone with something at the softer end of the scale. Easy to swap for stiffer tube if required.

Not sure what's next actually. Probably time to freeze development and get some use out of it!

a core plug could be a very simple effective way of keeping the oil in or out the shafts depending on which end you it it to

a core plug could be a very simple effective way of keeping the oil in or out the shafts depending on which end you it it to

Comment