Re: Ford Fiesta 1400cc race car

great evolution to the car!!! good job and keep the story coming!

great evolution to the car!!! good job and keep the story coming!

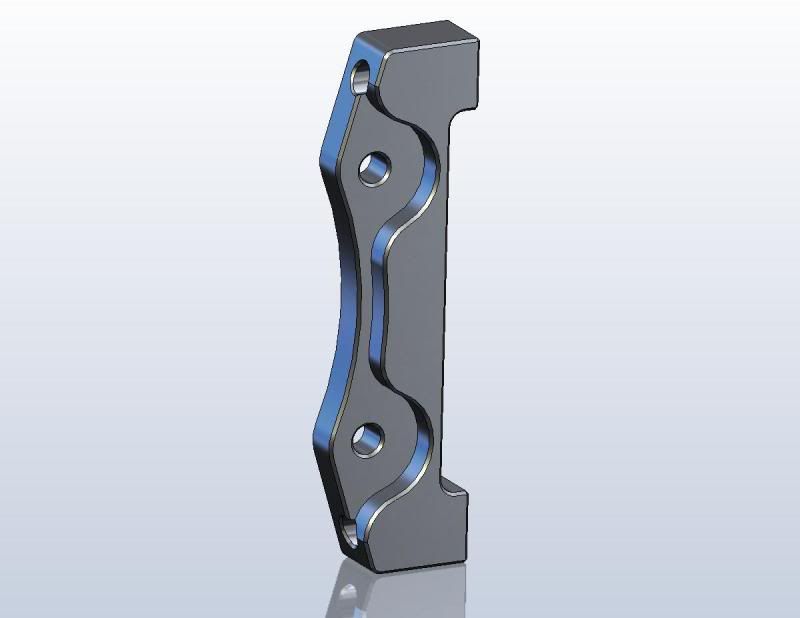

really like your pedal box assemly, tis nice that is

really like your pedal box assemly, tis nice that is

really like your pedal box assemly, tis nice that is

really like your pedal box assemly, tis nice that is

Comment