Re: Escort Sigma 1600 Race Car

New one on me too, never come across that before. We sometimes dowel the crownwheel onto the LSD body, taking the sheer loads off the CW bolts, as they're only just up to the job especially on big bangers with dog boxes...

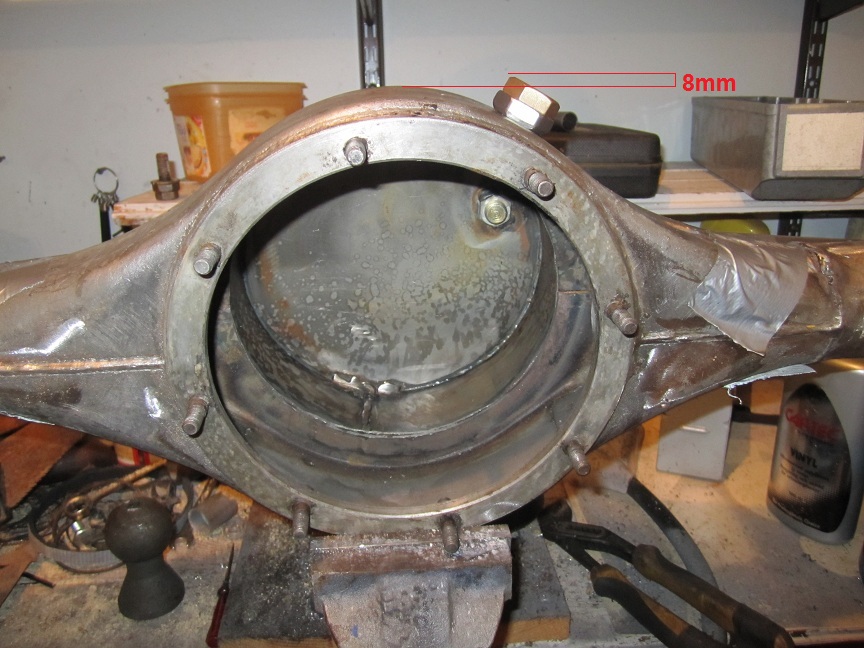

Anyway, back to the English, have you considered having your chosen cw&p shotpeened? It gives an increase in strength and a big increase in fatigue resistance... Might just make the difference. The one in this picture below has been shot peened and super-finished which further helps with lubrication as much as anything. Not cheap process though, I'm afraid.

New one on me too, never come across that before. We sometimes dowel the crownwheel onto the LSD body, taking the sheer loads off the CW bolts, as they're only just up to the job especially on big bangers with dog boxes...

Anyway, back to the English, have you considered having your chosen cw&p shotpeened? It gives an increase in strength and a big increase in fatigue resistance... Might just make the difference. The one in this picture below has been shot peened and super-finished which further helps with lubrication as much as anything. Not cheap process though, I'm afraid.

Comment