Re: Escort Sigma 1600 Race Car

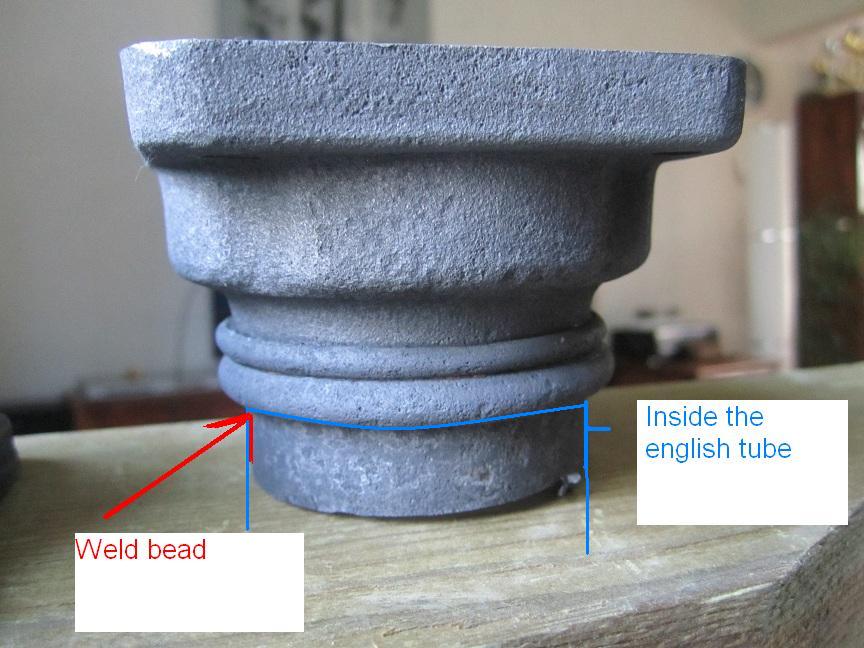

We did the same mod to an atlas cover plate and left a step at the bottom where we broke into the std cover in an attempt to catch metal particles in there with a magnetic drain nut at the bottom and a second fill level hole half way up the cover, worked well, Torsten makes good parts, I am sure those shafts will work well, being able to change the bearings at a race is a good point, the std shafts walking outward is due to the bearing collar being too loose of a press fit, it needs to be much tighter, then there is no trouble at all, had the same trouble with brake pads backing off due to the std bearing collars not gripping tight enough, some mild steel rings with a smaller ID heated and dropped on the shaft + quenched with oil cure the problem entirely, same trouble with english shafts bearing collars with only a slight press fit and inside rear wheels walking away round corners lol!

We did the same mod to an atlas cover plate and left a step at the bottom where we broke into the std cover in an attempt to catch metal particles in there with a magnetic drain nut at the bottom and a second fill level hole half way up the cover, worked well, Torsten makes good parts, I am sure those shafts will work well, being able to change the bearings at a race is a good point, the std shafts walking outward is due to the bearing collar being too loose of a press fit, it needs to be much tighter, then there is no trouble at all, had the same trouble with brake pads backing off due to the std bearing collars not gripping tight enough, some mild steel rings with a smaller ID heated and dropped on the shaft + quenched with oil cure the problem entirely, same trouble with english shafts bearing collars with only a slight press fit and inside rear wheels walking away round corners lol!

Comment