Re: Escort Sigma 1600 Race Car

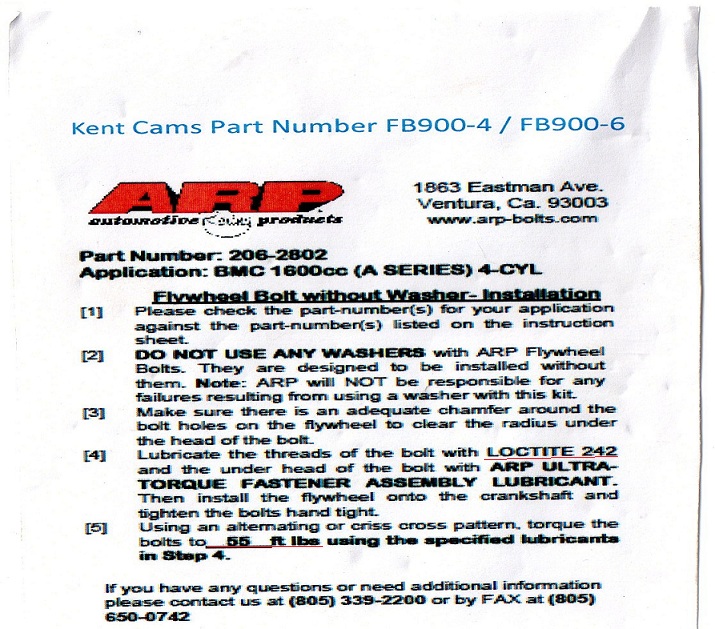

Yes they do have a good grip, its just the closer the head of the bolt is to the diff the better imho to resist any unwanted movement from the shearing action of the crown wheel, for example I would prefer to use flywheel bolts without any washers, less risk of the movement imho, a small factor but I believe it counts in an application like this with shearing forces

Yes they do have a good grip, its just the closer the head of the bolt is to the diff the better imho to resist any unwanted movement from the shearing action of the crown wheel, for example I would prefer to use flywheel bolts without any washers, less risk of the movement imho, a small factor but I believe it counts in an application like this with shearing forces

I need 12 point 9/16" socket. And as I live in the middle of nowhere, surrounded by wolves and polar bears, no dealer in 60km radius has one for sale. And for the very same reason I could not find the Loctite 242 sealent and had to settle for 243. Do not know the difference though. Nor did the clerks, wolves or polar bears. Tomorrow I'll continue my hunt for the 9/16

I need 12 point 9/16" socket. And as I live in the middle of nowhere, surrounded by wolves and polar bears, no dealer in 60km radius has one for sale. And for the very same reason I could not find the Loctite 242 sealent and had to settle for 243. Do not know the difference though. Nor did the clerks, wolves or polar bears. Tomorrow I'll continue my hunt for the 9/16

but I'd say that'll do.

but I'd say that'll do.

Comment