Escort Sigma 1600 Race Car

Collapse

X

-

Re: Escort Sigma 1600 Race Car

Thats not necessary with the ARP strech gauge. The spring in the gauge is stronger than regular Dial gauges and is not affected by the weight of the gauge. It can clamps itself to the bolt and stay there on its own. It needs to be set to .2" - .4" pre tension and then zero the dial prior to streching the bolt. Once set it really is quite straight forward job, and not too slow. You do not need to set it up again for every bolt just put it in place and zero the if needed."Failure is always an option." - Adam SavageComment

-

Re: Escort Sigma 1600 Race Car

No you did nothing wrong. The bolt strch method is more of a show off than the only way to tighten the con bolts. It is the most accurate way though. The only way you can be 100% sure the bolts are as tight as they can be. Nothing wrong with the 90% percent though.

Though when using a torque wrench the correct procedure is tho tighten it down and loosing up twice and leaving to the desired torque the third time. Using the ARP grase to the thread and under the head."Failure is always an option." - Adam SavageComment

-

Re: Escort Sigma 1600 Race Car

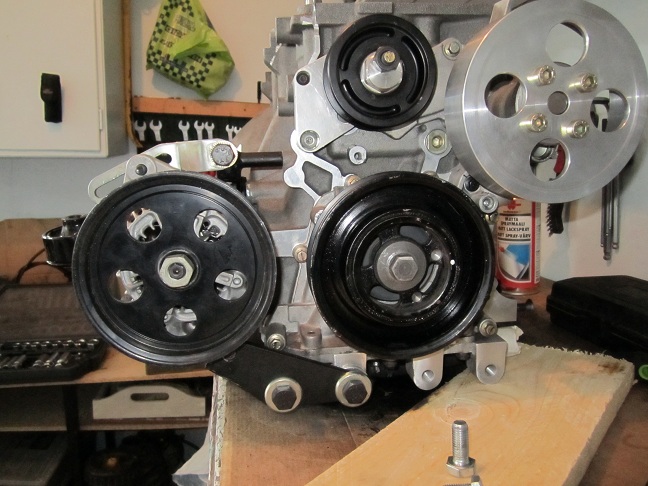

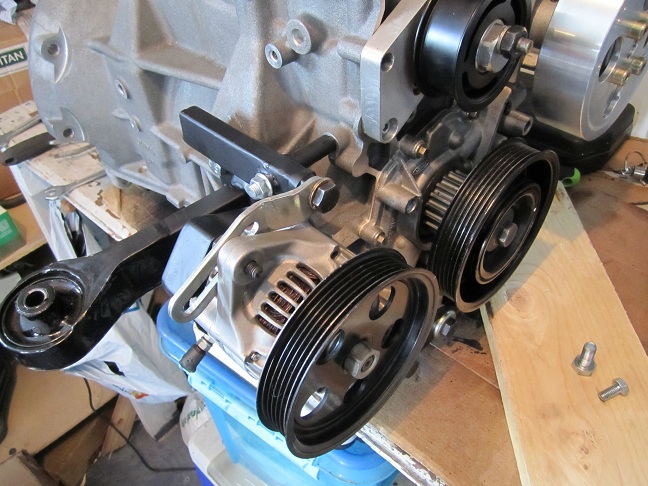

Today I have mostly wrestled with the g*d damn alternator placing issues.

I noticed the bracket I'd done earlier would not work. The alternator belt would faul to the bolt head holding the alternator

The behemoth pulley made it pretty difficult to make a strong enough bracket and to avoid the belt scrubbing to the bolt head.

But after some serous head scratching I think I finally solved this alternator re-positioning issue.

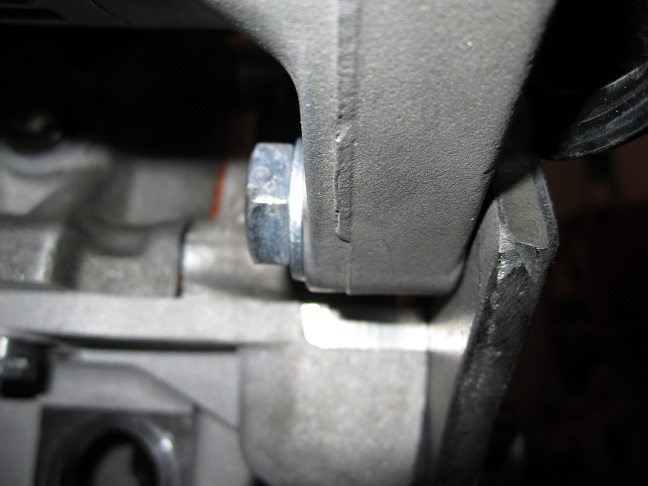

8mm flat iron. It's as thik as I can use here.

Inserted a Helicoil thread fot the alternator

Bolted the alternator to its bracket from the behing. No bolt head for the belt to rub into.

The pulley is quite close to the bracket.

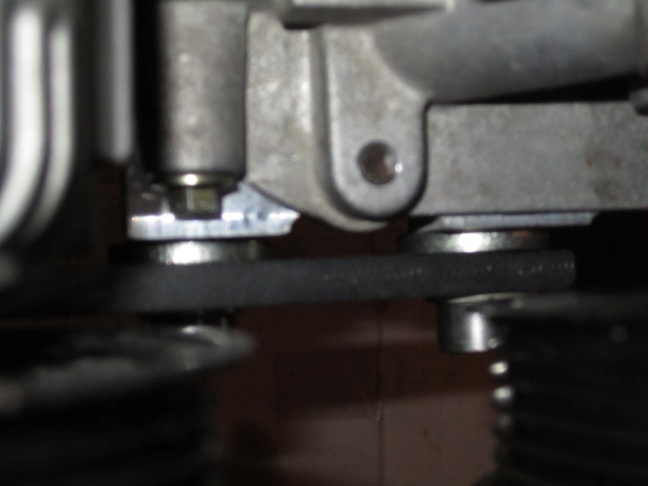

Then some spacers to get the alignement right

And there you go. The down side to this new position is the belt wrap on the crank pulley. I believe the belt will cower approx third or so of the pulleys circle so hope it will not slip.

Still need to do the adjustmet bar.

And that's all I have to say about the alternator..."Failure is always an option." - Adam SavageComment

-

Re: Escort Sigma 1600 Race Car

THe other thing with a torque wrench is that the final tightning should be done is a single smooth movement until the wrench torques out. When using the the proper arp grease this gives the most repeatable torque setting. The stretch method is the most accurate but requires a bit more work and is not necessary unless building a race / rally engine.To finish first, you must first finishComment

-

Re: Escort Sigma 1600 Race Car

I wouldn't say its necessary even on competition engines. But recommendable none the less. It kind of depends on the nature of the engine.THe other thing with a torque wrench is that the final tightning should be done is a single smooth movement until the wrench torques out. When using the the proper arp grease this gives the most repeatable torque setting. The stretch method is the most accurate but requires a bit more work and is not necessary unless building a race / rally engine.

But it is certainly more accurate / better way to get the best out of the con rod bolts. People have gotten away with simply torquing the bolts up for decades.

I'd say its well worth the effort just for the extra bit of reliability and for the peace of mind.Last edited by Roadsport; 30-03-2011, 05:17."Failure is always an option." - Adam SavageComment

-

Re: Escort Sigma 1600 Race Car

I have to say i don't agree with that, brand new torque wrenches can be off by a big margin, and in a race engine too much or too little torque on the rod bolts could potentially lead to an engine failure.

Some of the smaller bolts require only 28lb/ft or less torque, that is very critical in my opinion as it is a very low figure, with an engine like that torquing the bolts using as stretch gauge would be essential for racing.

I beleive the whole point of using a stretch gauge is to eliminate any incorrect torque valve readings on your torque wrench, even the best torque wrenches loose their accuracy over time and have to regularly be re calibrated.

About torquing the bolts 3 times that is not strictly necessary when using ARP lube, have a look at the chart here:

According to that chart near the bottom of that page you get slightly less preload on the third tightening of the bolt with ARP lube, the first tightening giving the best preload, but there is nothing wrong with torquing them 3 times either as it may help to polish the threads a little.Last edited by RWD fords rule; 30-03-2011, 12:36."Horsepower sells cars, torque wins races" - Enzo FerrariComment

-

Re: Escort Sigma 1600 Race Car

I do agree with both of you that it is the best method. Especially on these tiny bolts. Thats why I bought the gauge.

But honestly I bet most competition engines by far are built with the traditional torque wrench and are fine. But there is a risk involved no doubt. I've raced since -01 and this is the first time I'm using the strech gauge. But as they say ignorence is bliss. Now that I know difference between these two methods I doubt I'll ever go with the torque wrench again."Failure is always an option." - Adam SavageComment

-

Re: Escort Sigma 1600 Race Car

Totally agree, once you know a better way of doing something and have the tools to do it you are spoilt from then on lol

That looks like a very good stretch gauge btw "Horsepower sells cars, torque wins races" - Enzo Ferrari

"Horsepower sells cars, torque wins races" - Enzo FerrariComment

-

Re: Escort Sigma 1600 Race Car

It was simple and very easy to work with due to the stiff spring in the dial gauge . Alltought the experince so far is very limited. But it was a fine untill I snaped the spanner. Ordered a new one today. Snap on as suggested above."Failure is always an option." - Adam SavageComment

-

Re: Escort Sigma 1600 Race Car

The Truetrac lsd is now fitted. No pics of the actual process. The work was done by my old man. A long retired mechanic who now passes time building up Historic racing cars. He really has an eye for setting up CWP. Which I lack.

Now it needs to be bent and painted before re installing it.

Heres the axle. A Mustang -94 7.5" rear end. Shortend to english lenght and fitted with billet Ford 9" housing ends and custom made drive shafts to take the Atlas GP1 flanges and the 9" wheel bearings. Fitted with Richmond 5,13:1 CWP

It was somewhat justified with the very torquey Pinto but now feels a bit of an overkill. Works like a treat though and gives very nice feel to the rear brakes due to big enough wheel bearings. No soft pedal at first push at all.

The head is now undoergoing the modifications so hopefully will be done soon. I'll get the Axle bent while picking up the head so hopefully they'll bot be done soon. The tracks open in amonth so I hope I could get few outings before the season starts in June.

Ordered the Snap on spanner. Should be with me some time next week."Failure is always an option." - Adam SavageComment

-

Re: Escort Sigma 1600 Race Car

I'm going out of my mind just sitting and waiting for the darn head.....

I see the car coming together In the very last possible moment again with no actual time to do some propper testing.

I'ts like the Ground Hog day with this car. Same thing every year...

Evenn the 3/8" spanner had to be ordered from UK and still haven't arrived

Well, I try to keep busy and sort all the minor things whilw waiting.

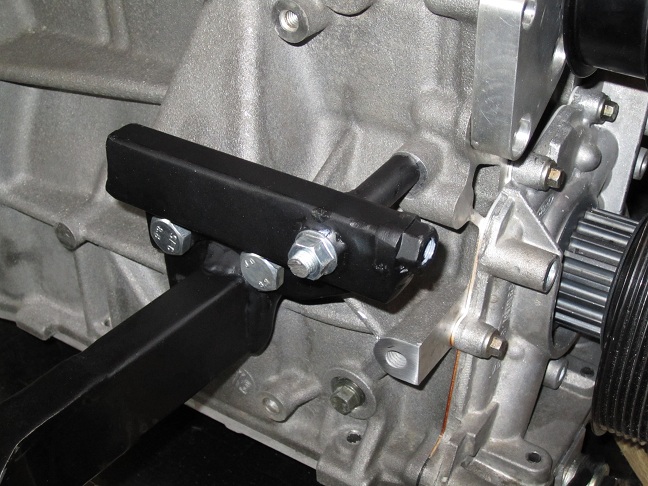

Finished the Alternator brackets today. Atleast its now sorted and Im happy with it. It sits MUCH lower now and on a more favourable side of the engine. And makes for a easier removal of the aux belt. And gives more room to work on the throttle body side.

The upper bracket. HAd some hard time figuring out how to make a sturdy mounting point for the tensioner bar.

Here mounted on the block

And fitted with the alternator. It sure feels solid enough and if this won't hold then I guess ot'll come off....

I reckon it has a nice travel too for easy belt install.

As I said I have too too much time (when the missus is not keeping me busy) so I decided to copycat some of the nice rocker covers I've seen here. Only this is the oil sump so no one will bee watching it. Except the scruteneers.

I guess next I'll dismantle the Titan oil pump. It had a tiny leak at the end of it. Theres a nut on the back of the pump that developed a drop of oil on it every once and again.

And insert helicoils to mend the dodgy threads on the oil pump mounting plate.Last edited by Roadsport; 10-04-2011, 10:12."Failure is always an option." - Adam SavageComment

Comment