Re: A race bmw 316, 240bhp Atmo M10

well its going to get a stroker crank, not sure yet whether to go for 91 or 91.6mm, need to get the block honed to see if it will go again, if it wont i will need a new block and will go with 91.6 stroke, if the current block will go again i might sick with a 91mm stroke due to block height issues i.e the current one has had quite a few skims in its life.

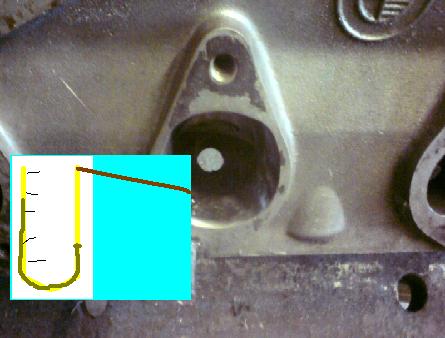

also plannned is to borrow use of dave walkers flowbench some more to see which head casting to go with

well its going to get a stroker crank, not sure yet whether to go for 91 or 91.6mm, need to get the block honed to see if it will go again, if it wont i will need a new block and will go with 91.6 stroke, if the current block will go again i might sick with a 91mm stroke due to block height issues i.e the current one has had quite a few skims in its life.

also plannned is to borrow use of dave walkers flowbench some more to see which head casting to go with

.jpg)

Comment